Chesterton will be featuring the 4400 Dual Concentric Gas Seal. Designed for ANSI/API pumps, mixers, compressors, and blowers, The 4400 Gas Seal provides zero fugitive emissions sealing with minimal barrier gas consumption. Due to the efficiencies of the dual concentric design and the In-Gland Control System, only a fraction of the overall gas consumed is introduced to the process. The remainder of the gas introduced to the seal is transferred to the atmosphere after performing the critical function of face separation.

Chesterton 442 Split Seal features a factory split design ideal for equipment that is difficult and time-consuming to disassemble, such as large vertical and horizontal split-case pumps. The seal is assembled without adhesives, allowing for easy installation. The 442 Split Seal can be maintained in the field with low-cost repair kits, which reduce ongoing maintenance costs. The compact design of the 442 Split Seal can be used in a wide variety of equipment and process fluids.

Chesterton DualPac 2212 is a high-performance, non-staining, multipurpose braided packing that requires fewer gland adjustments than traditional packing. The packing’s shaft side is made from highly resilient fiber that is burn-resistant and long-lasting, which minimizes shaft scoring. DualPac 2212 can be used in the following applications: ore slurries, mineral handling slurries, dewatering, stock, sludge, slurry and process pumps, agitators, and mixers.

SpiralTrac Environmental Controller throat bushing

SpiralTrac Environmental Controller throat bushing

The SpiralTrac Environmental Controller is a throat bushing engineered to transform and control the internal stuffing box environment in rotating process equipment to reduce downtime and extend equipment life. SpiralTrac enables particulates to be removed from the stuffing box and away from packing or mechanical seals and permits air to evacuate the stuffing box upon flooding to retain cooling. Heat buildup is minimized in the stuffing box creating circulation around seal faces. SpiralTrac is offered in four configurations: split, adapter, standard, and packing.

The Chesterton Connect Equipment Monitoring System monitors and analyzes equipment health 24/7. The Connect sensors and gateway automatically collect and transfer the equipment operating conditions in near real-time to the Chesterton Connect Cloud dashboard, simplifying remote monitoring of equipment to help improve operations.

ARC Industrial Coatings provide long-term protection to systems and equipment exposed to erosion, corrosion, and chemical attack. ARC coatings are ceramic-reinforced and abrasion-resistant and can handle 100% solids and high-temperature.

chesterton.com

ABB—Booth 2835

ABB will present key examples of its full range of energy-efficient Baldor-Reliance motors at TPS. ABB products are engineered with industry-proven designs that reach new levels of efficiency under the most demanding conditions.

ABB offers a wide variety of Baldor-Reliance motors to meet specific pumping needs. Repeatable quality in manufacturing and unmatched service makes Baldor-Reliance the most preferred NEMA motors in the industry. The Baldor-Reliance motor showcase will cover a wide offering of explosion-proof and severe-duty motors.

All Baldor-Reliance three-phase motors are designed for inverter duty. The Baldor-Reliance EC Titanium integrated motor/drive is designed for maximum efficiency. These motors are suitable for constant or variable torque applications while still offering excellent performance across a wind speed load range.

ABB Baldor-Reliance 841XL.

ABB Baldor-Reliance 841XL.

ABB delivers a wide offering of explosion-proof and severe-duty motors including the Baldor-Reliance IEE 841XL with a patented positive lubrication system (PLS), extending motor life in harsh environments. The severe-duty lineup also includes the IEEE 841XL vertical P-base motor with IP55 sealing and winding insulation, suitable for inverter use, making this motor ideal for harsh pumping applications.

www.baldor.com

us.abb.com

Velo3D—Booth 1419

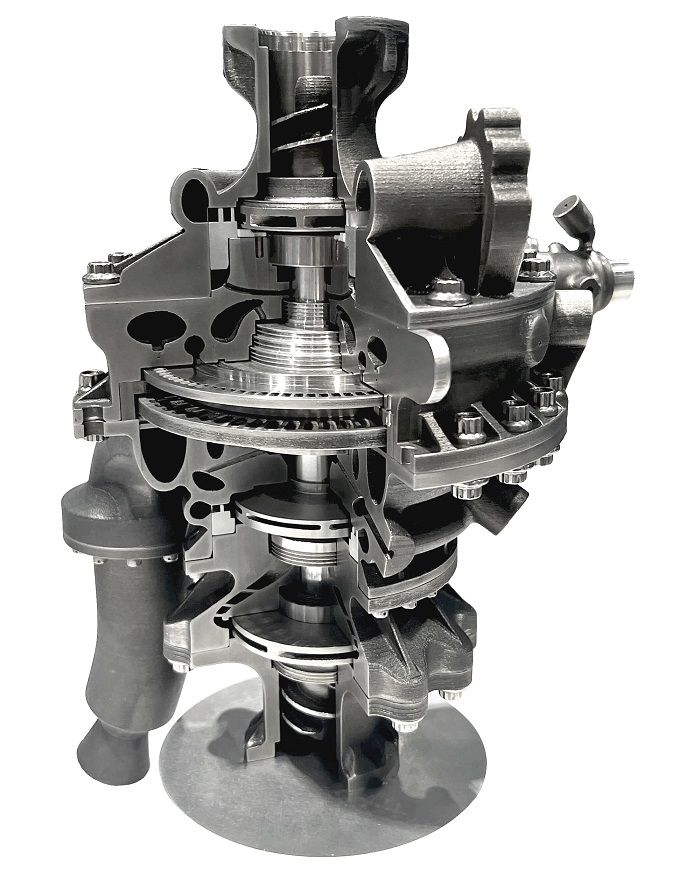

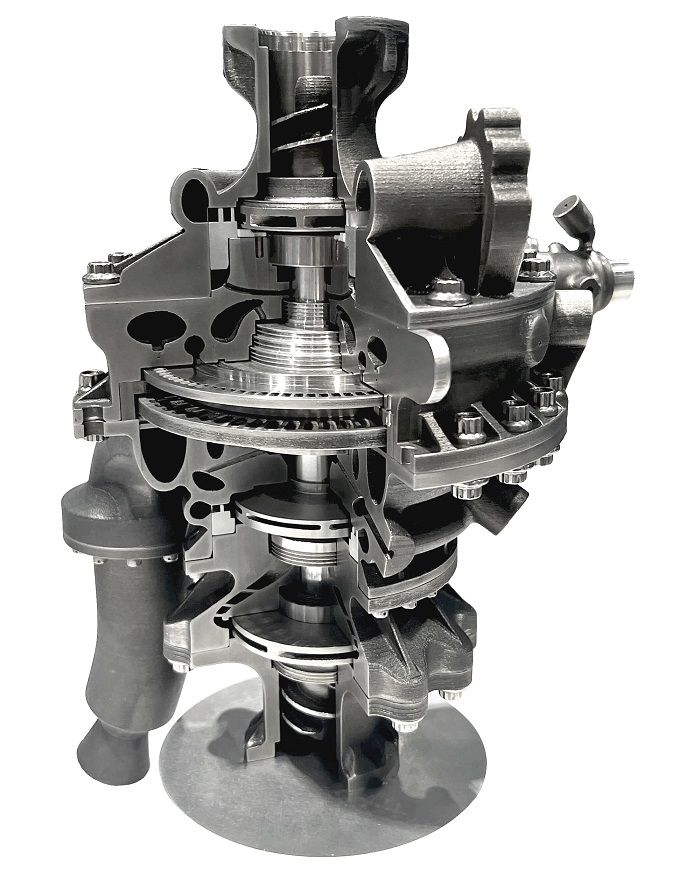

At this year’s TPS Conference, Velo3D will be displaying some new turbomachinery parts, including an entire turbopump that was designed by two students from Colorado University Boulder’s Aerospace Engineering Sciences program. The turbopump is more than 95 percent 3D printed—everything except the shaft, spacers, and bolts were 3D printed on a single build using a Sapphire XC. The display is a good example of how metal 3D printing can democratize the design and manufacture of turbomachinery parts, as even two students can have their designs manufactured, finished, and tested.

This rocket turbopump was printed in Inconel (IN718), a precipitation-hardenable nickel-based superalloy known for its superb tensile strength when subjected to extreme pressure and heat.

This rocket turbopump was printed in Inconel (IN718), a precipitation-hardenable nickel-based superalloy known for its superb tensile strength when subjected to extreme pressure and heat.

Sid Raje on the Velo3D team will also be presenting on the functional benefits of additively manufactured turbomachinery impellers. Sid works closely with Velo3D’s customers in the turbomachinery industry to help them with the designs and build of their inducers, impellers, volutes, and other turbomachinery parts. He’ll be discussing how 3D printing can help produce more performant designs, streamline supply chains, shorten lead times, and in some cases even lower production costs compared to conventional manufacturing.

In addition to the turbopump (pictured), Velo3D’s booth will also have a number of turbomachinery parts on display, including a shrouded impeller produced on its Sapphire XC printer, which is capable of printing parts up to 600 mm in diameter.

velo3d.com

Ingersoll Rand—Booth 2635

With over 145 years of knowledge and expertise, Ingersoll Rand is a global manufacturer and distributor of unrivaled compressed air and gas solutions, parts and accessories, and service solutions for a wide range of industries and applications. For decision-makers seeking a robust and energy-efficient compressed air system for oil and gas compression in critical industries, Ingersoll Rand offers a wide portfolio of state-of-the-art products. This includes the new MSG NX 30000 Centrifugal Air & Gas Compressor that meets the demands of energy-intensive sites while making a substantial difference to a business’s bottom line, through a range of proven technologies and features. Designed with air separation and industrial gas applications in mind, Ingersoll Rand’s MSG NX 30000 centrifugal compressor provides industry-leading efficiency and lower overall total cost of ownership in an optimized, easy-to-maintain package.

Built on a common base with robust components, MSG NX compressors undergo a vigorous testing and validation process to ensure superior performance even under extreme conditions. Available in many configurations, the MSG NX 30000 can be tailored to meet your precise needs. Features like the cost-saving variable inlet guide vanes provide up to nine percent power savings compared to alternative technologies and result in big savings on your energy bill.

Ingersoll Rand’s new MSG NX 30000 centrifugal air and gas compressor.

Ingersoll Rand’s new MSG NX 30000 centrifugal air and gas compressor.

Delivering reliable compressed air and gas to your process goes well beyond the compressor itself. To maximize performance, it is imperative to manage the entire lifecycle of your compression system. In addition to Ingersoll Rand’s portfolio of compressed air and gas systems, they offer extensive service programs that allow you to partner with their experts to optimize your total cost of ownership and enhance system reliability. From regular maintenance with OEM-certified parts to remanufacturing aging equipment, Ingersoll Rand provides the industry’s most comprehensive resource for advanced aftermarket products and field service.

ingersollrand.com

For additional information on the show visit:

tps.tamu.edu/

Power Transmission Engineering is THE magazine of mechanical components. PTE is written for engineers and maintenance pros who specify, purchase and use gears, gear drives, bearings, motors, couplings, clutches, lubrication, seals and all other types of mechanical power transmission and motion control components.

Power Transmission Engineering is THE magazine of mechanical components. PTE is written for engineers and maintenance pros who specify, purchase and use gears, gear drives, bearings, motors, couplings, clutches, lubrication, seals and all other types of mechanical power transmission and motion control components.