Ball Bearing Limiting Speeds

Well, I am happy to be back here at PTE! It has been a few years since I have been able to write casually due to some legal structures in my company. Coincidentally, those barriers were removed not long before PTE Sr. Editor Matt Jaster reached out to me to ask if anything had changed with my disposition. Additionally, I recently started working on a couple of topics with ABMA (now managed by AGMA), which I won’t get into just yet, and then discovered through Matt that AGMA and PTE have also joined ranks. What a great combination, very exciting developments in bearing land, indeed!

While we have been out of contact, COVID has been running almost in parallel with the unprecedented electric revolution in the automotive industry. When the COVID shutdowns started, I thought we had—maaaybe—five years before everything looked like a post-nuclear apocalypse out of a movie. Somehow, in a page out of bizarro-land, this electrification wind sprint started around the same time as COVID and made us all busier than ever!

Figure 1: NSK E1102k 2012. B10

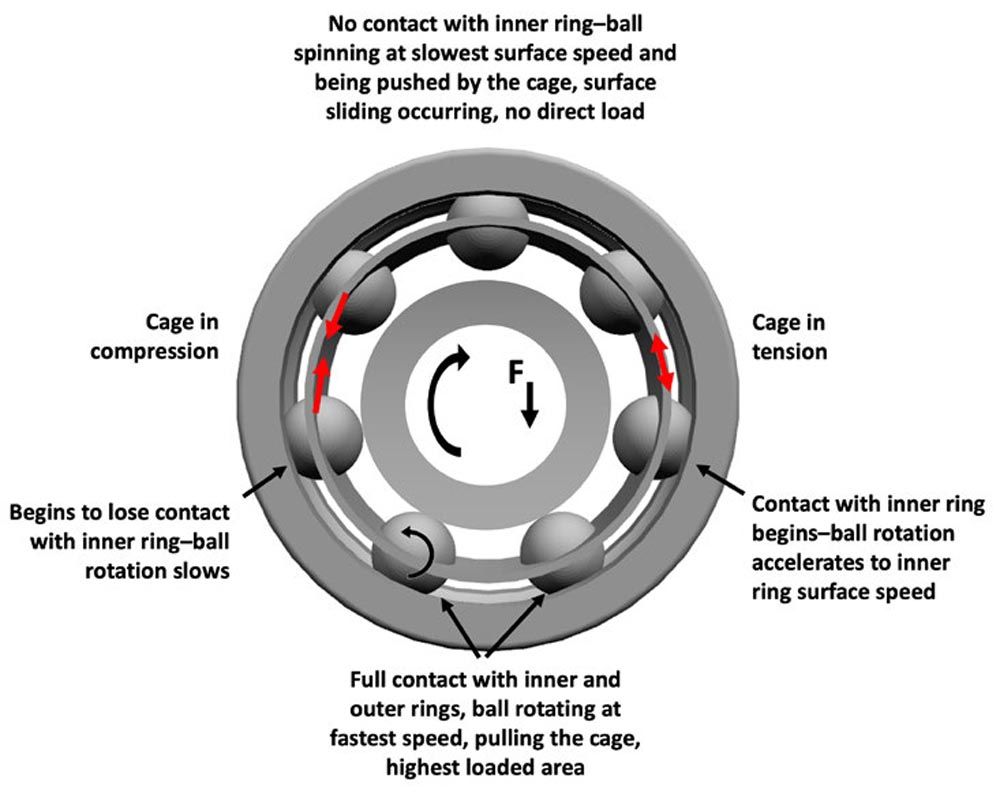

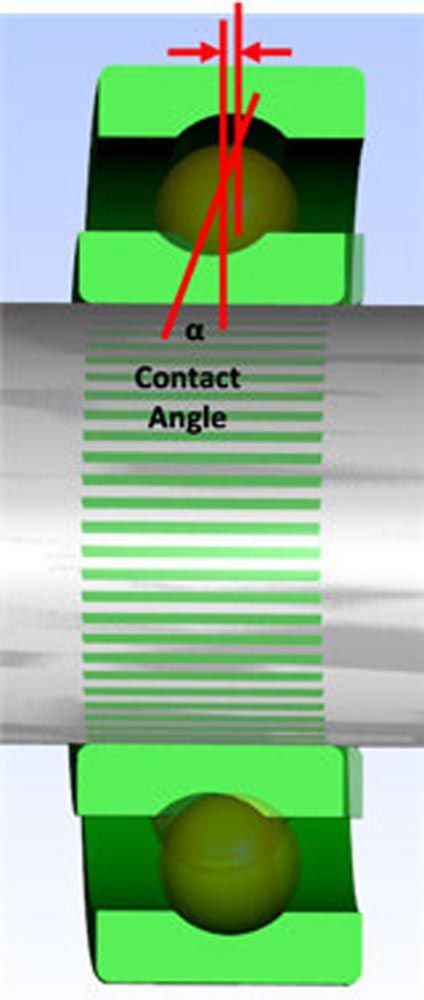

Electrification has really brought ball bearings back into focus as the primary bearing in our drive systems. Some boxes have tapers on the slower shafts for stiffness and others are using a ball/cylindrical combo for efficiency. Regardless, we all face the same challenge on the primary shaft in dealing with the potential of 18,000–20,000+ rpm speeds coming out of the motor. Plenty of applications run 20,000 rpm; what makes the automotive motor unique is, in addition to speed, we are driving huge torques, frequent torque reversals and a huge range of temperatures both internally and geographically. Of course, this all needs to be suited for high-volume manufacturing as well. Adding full ceramic balls, a PEEK cage and a high precision classification is a really easy way to run greater than 20,000 rpm all day but is an expensive option. One bearing alone could hurt the cost competitiveness of your gearbox. In the case where a single bearing can change the landscape of your project, it is worth taking a little time to understand exactly what the drivers of our speed limitations are.

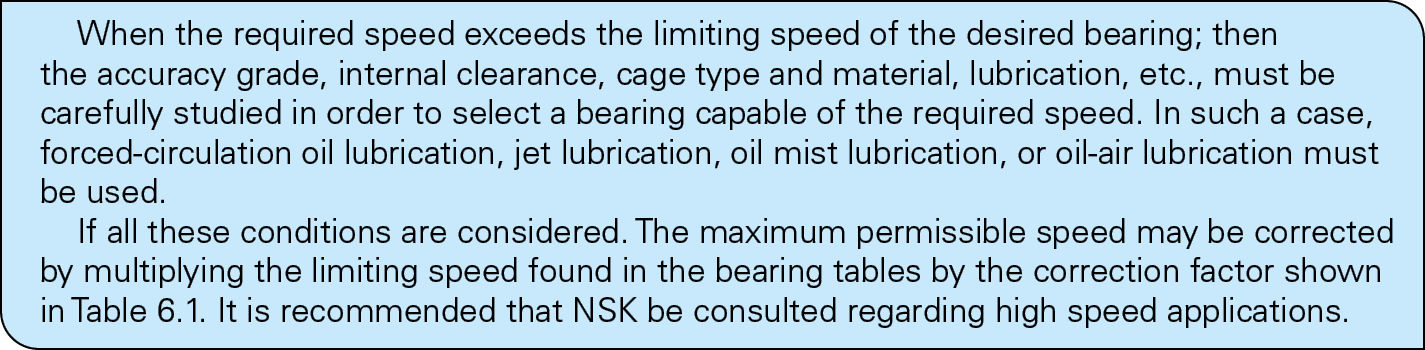

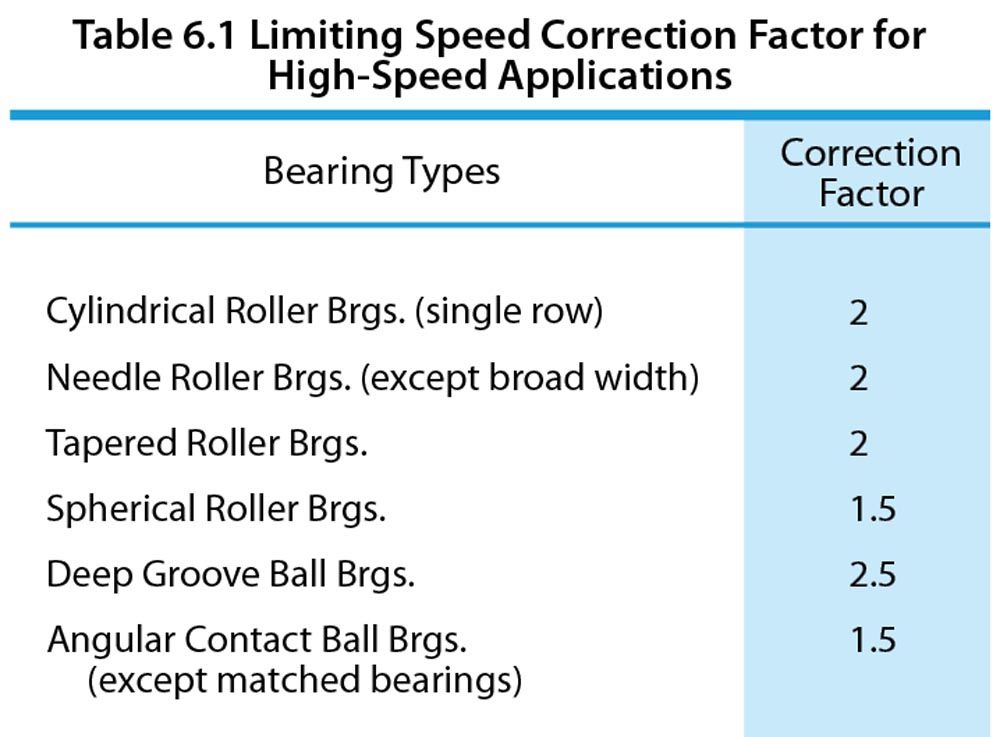

Due to the extensiveness of this subject, we will only discuss catalog Limiting Speed today which is a mechanical based speed rating. Thermal-based speed ratings are rooted in ISO 15312 and DIN 732 which we will cover next time. Those ratings discuss speed limitations solely based on the ability to keep the bearings thermally stable and make no assumptions about mechanical limitations.