Thermal Growth Issues and Solutions for Shaft Couplings

Thermal Growth Issues and Solutions for Shaft Couplings

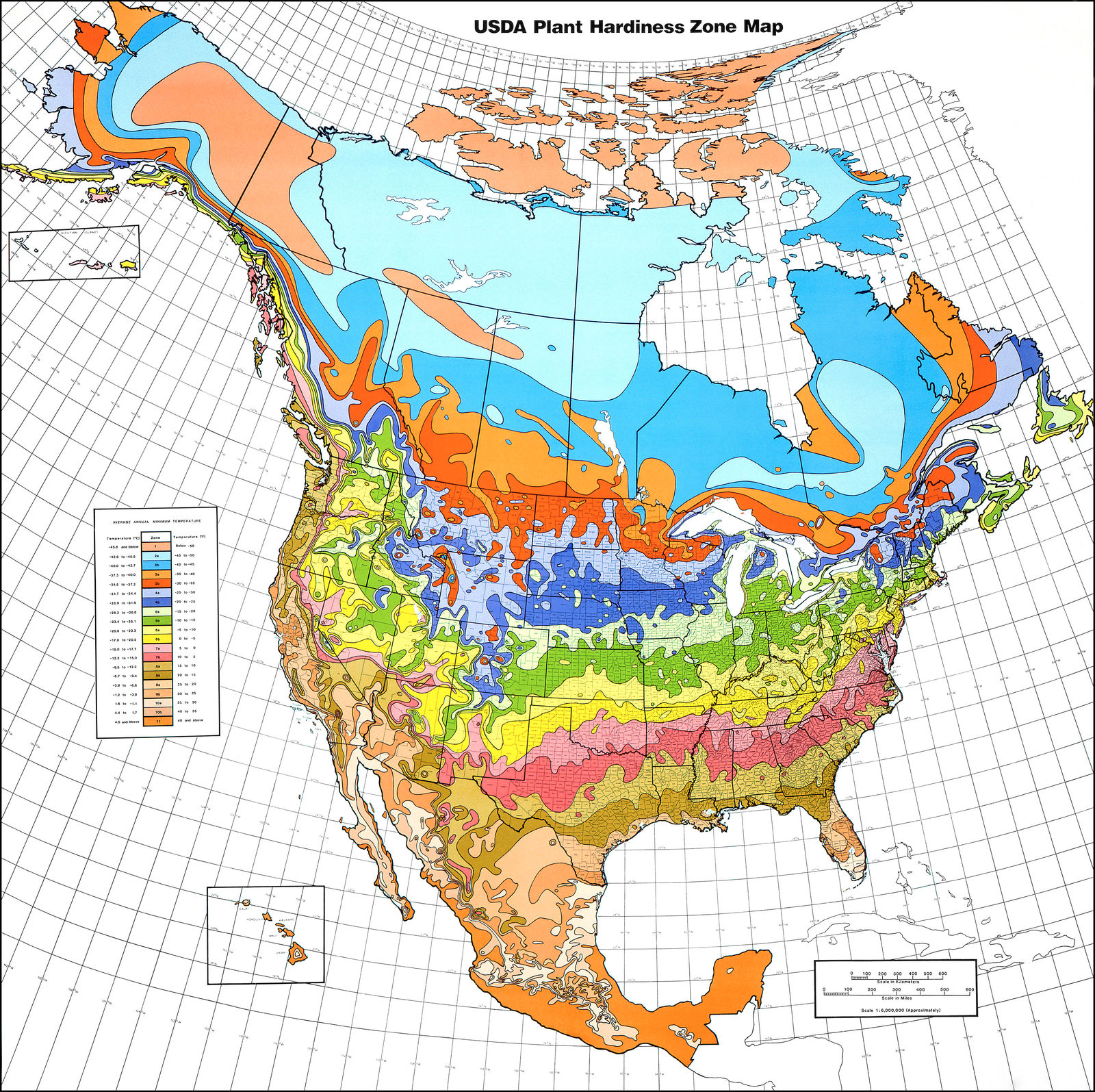

I have been researching “Thermal Growth” issues for decades across North America. Many refineries and chemical plants are built with large pieces of rotating equipment in an outdoor setting exposed to the elements. This means the equipment (driver and driven) are often seeing forces beyond anyone’s control called “Thermal Growth.” This is especially true in colder climates (Zones 1 to 4).

The trouble is that often the root cause of the coupling or bearing failure is not identified by the reliability team at the end-user level. The actual equipment foundation is seeing massive forces as the ground heaves to frost. These forces are slow and unavoidable — the result is a shaft misalignment. This is hard to detect if you do not know what you’re looking for, but the tell-tale sign is that this issue is seasonal. For example, the bearing or coupling fails every autumn or spring.

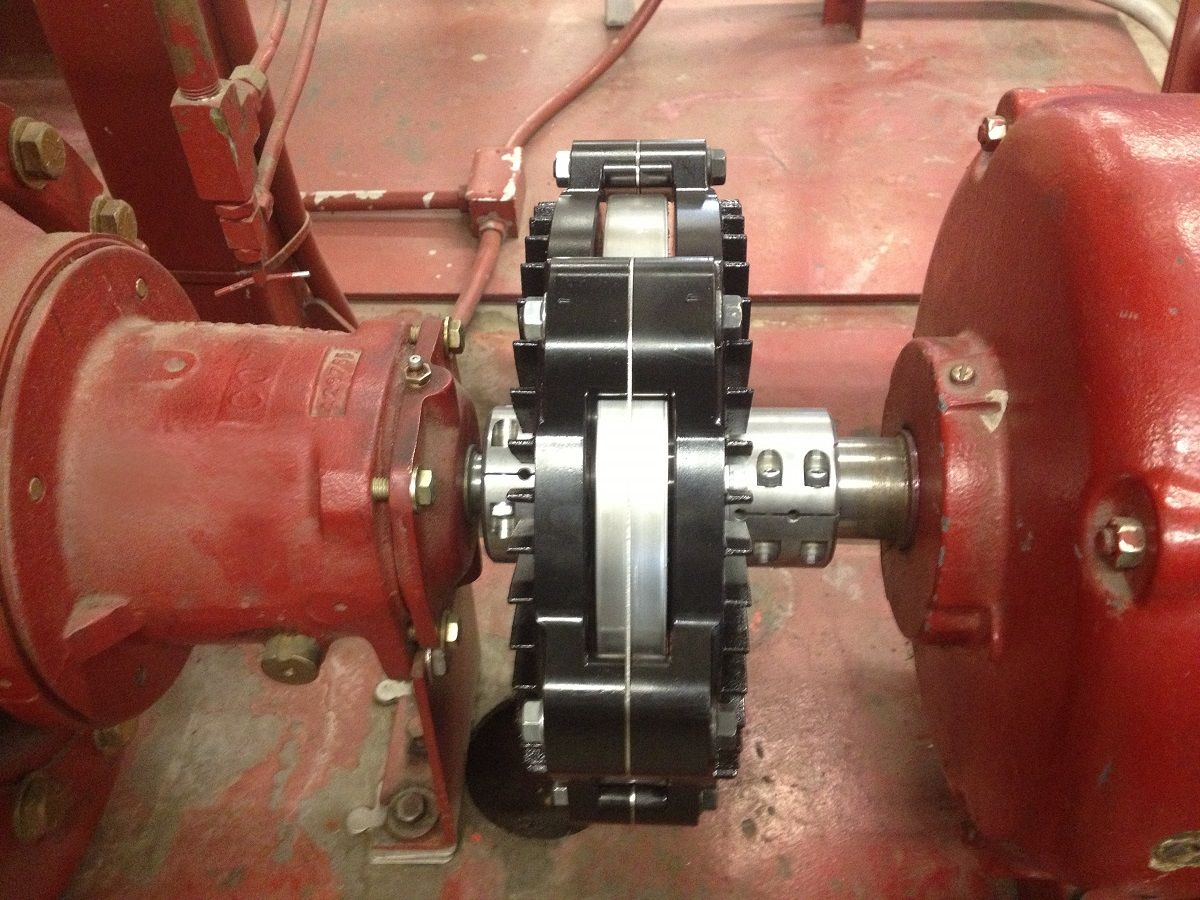

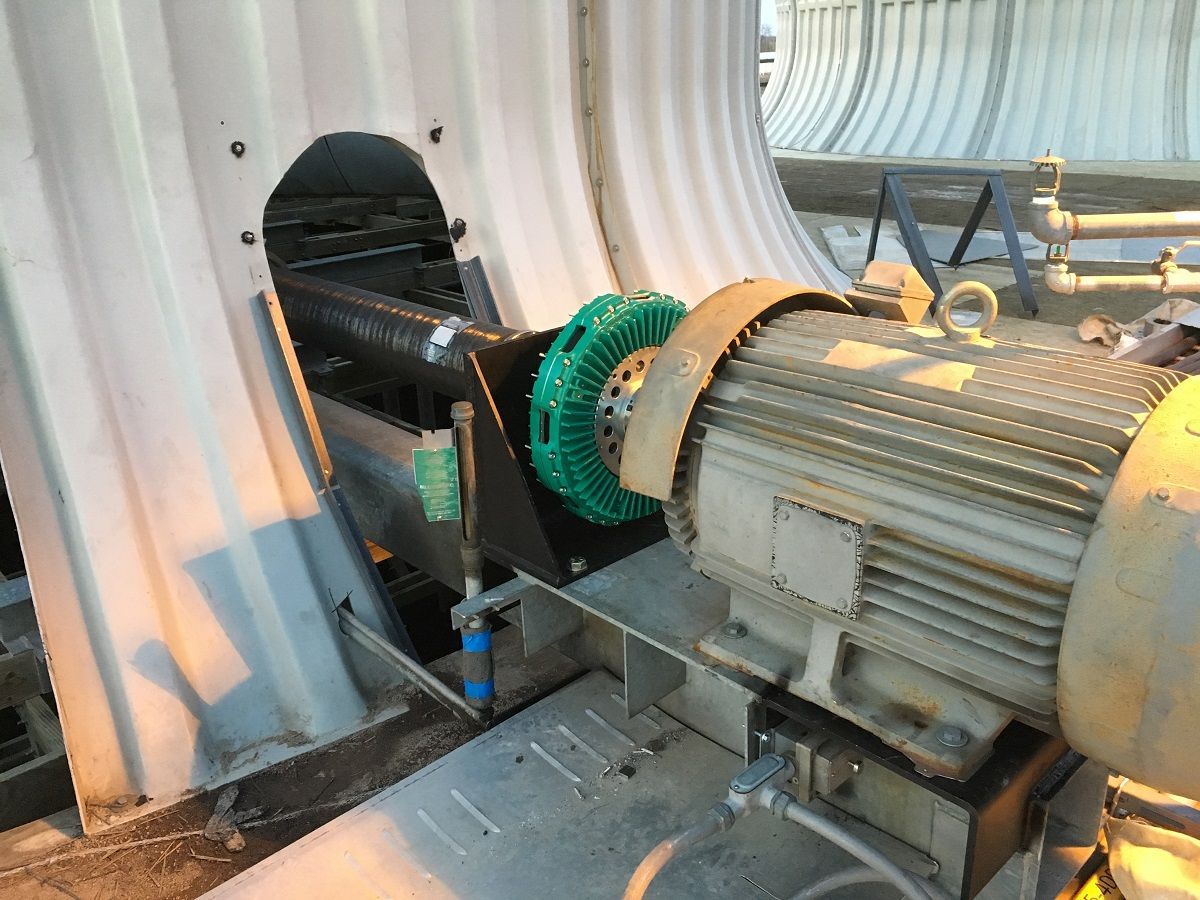

The first common mistake is when coupling failure is not properly recognized by maintenance. They often think they did a poor alignment job. As the coupling fails, they focus only on that part. They usually ask their power transmission supplier for a better shaft coupling that can handle more misalignment, which is the second mistake. They may also buy some laser alignment equipment to help with the process, which is never a bad investment. Many shaft coupling manufacturers advertise massive shaft misalignment capabilities, as that sells the product. Having a shaft coupling to handle excess misalignment is what the uninformed maintenance technicians are requesting. The issue is the coupling insert may be able to handle the misalignment, but the bearing on either side cannot, so we are simply passing the unidentified issue to the next piece of rotating equipment which is usually the bearings.

The next issue, after they feel they have solved the coupling, is the bearings start to fail (seasonally). The next call is typically to the bearing supplier, as the root cause has not been clearly identified yet. Now a process is started to redesign the bearings and find solutions to an unidentified rotating equipment condition. If the technician is lucky, he or she is calling the very same supplier who supplied the coupling. If the supplier has technical aptitude, they may start to ask some questions and realize this issue may be more than the local team thinks. First coupling issues, now bearing issues on the same unit?

In today’s fast-paced world it is easy to get blinded by too much information, yet not see the real issue(s). If the supplier or end-user has access (internally or externally) to an experienced rotating equipment specialist, this is the time to ask for outside technical support.