Our Publications

Please select a publication below.

Power Transmission Engineering

Publisher's Page

Back to TopFeature Articles

Back to Top2024 Trends in Fluid Power

AI, smart manufacturing, electric vehicles, and product specification highlights industrial shift

Read More

Technical Articles

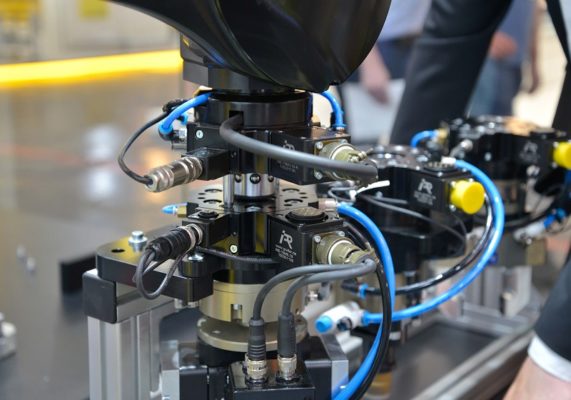

Back to TopBeyond Bearings: Unleashing the Potential of Ball Splines in Robotic Designs

The often-overlooked benefits of integrating high-speed, multiaxis motion on a single shaft

Read More

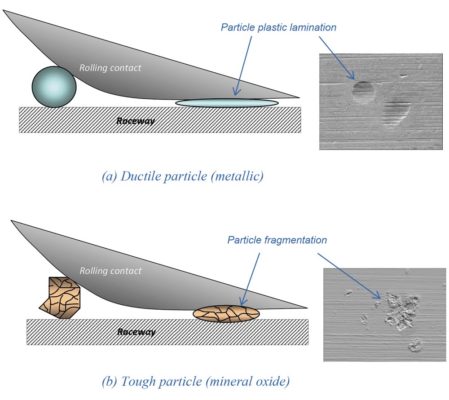

Spindle Bearings—Potential Damaging Mechanisms and Mitigation

Exploring contact conditions in both steel-steel and hybrid ceramic bearings

Read More