Custom Machine and Tool Bolsters Accuracy and Efficiency for Vande Berg Scales

Custom Machine and Tool Co., Inc.

Bolsters Accuracy and Efficiency for Vande Berg Scales

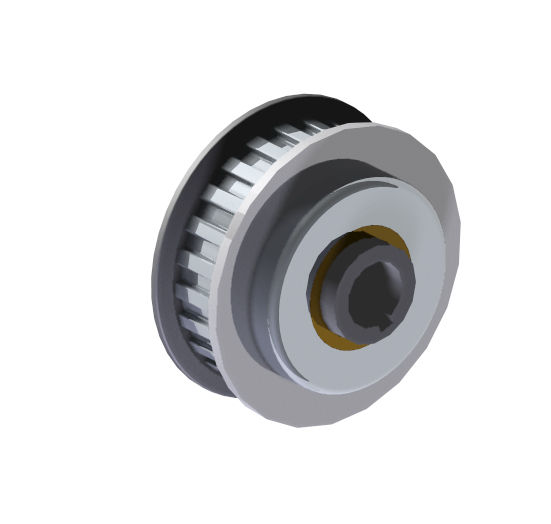

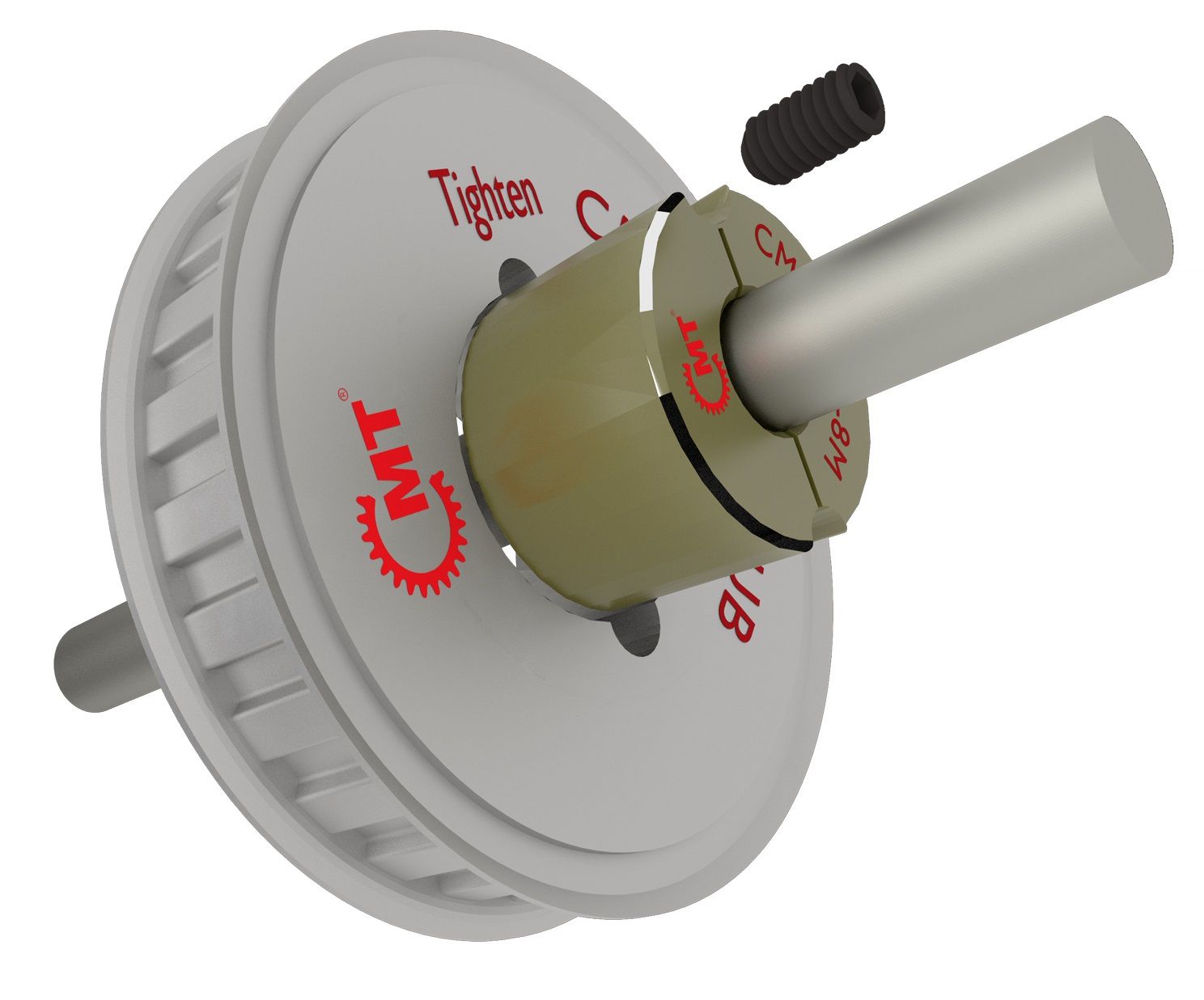

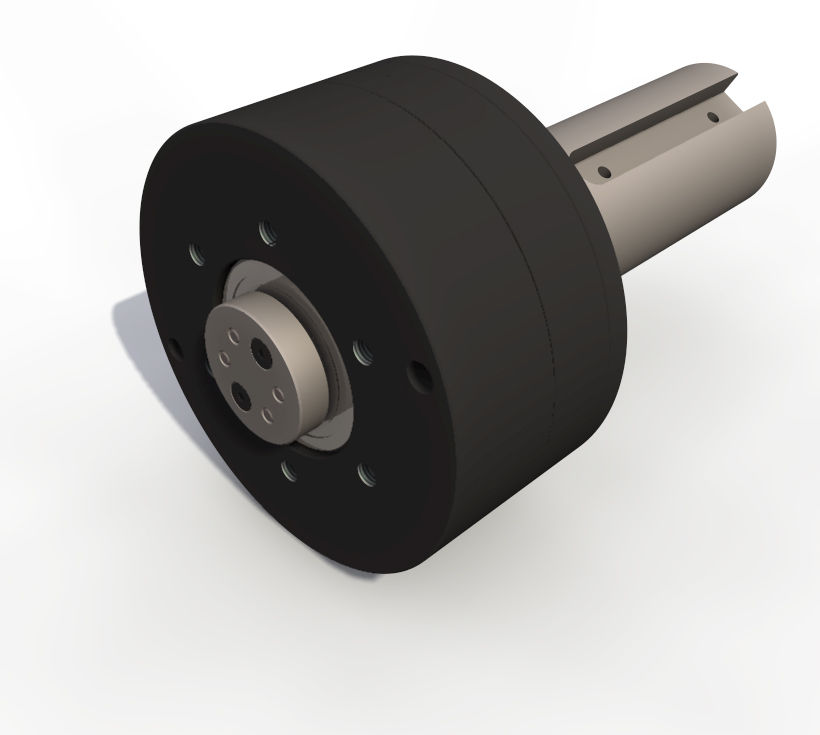

If you can find that magic bullet that will reduce the machining process, you can achieve meaningful efficiency gains. It is imperative that checkweighers or in-motion weighing systems remain both accurate and efficient while attaining a consistently smooth operation because they dynamically weigh products as they move across the belt. One such challenge David Vande Berg, president of Vande Berg Scales (VBS), encountered was to make sure the company’s in-motion weighing systems were equipped to move with less vibration and smoother transitions.

Based in Iowa in a 15,000 square foot facility, Vande Berg Scales manufactures a number of systems that employ motor driven belts and chains. The company designs and fabricates weighing and automation equipment including in-motion checkweighers, weight price labelers, box/tote weight labelers, and monorails. Accuracy through automation enables Vande Berg Scales to achieve the highest of quality standards. Add to this, their measurement and advanced design capabilities, VBS is able to facilitate custom projects and challenges with the same ease as standard products. For more than 30 of it 54 years, Vande Berg Scales has built a solid presence in the meat, dairy, food, and manufacturing industry as a driving force in dynamic weighing and automation.

Igniting the Passion for the Next Generation

In 1964, Don and Wilma Vande Berg tapped into their entrepreneurial spirit by converting their home and garage into small workshops to launch the Vande Berg Scales brand. VBS began to produce weighing, measuring and automation systems. The payoff came as the company quickly grew, thanks to their relentless ingenuity and dedication to their clients’ needs. This leap of faith laid the groundwork for the second generation. In 2001, David Vande Berg, son of Don and Wilma Vande Berg, purchased the company.

Power Transmission Engineering is THE magazine of mechanical components. PTE is written for engineers and maintenance pros who specify, purchase and use gears, gear drives, bearings, motors, couplings, clutches, lubrication, seals and all other types of mechanical power transmission and motion control components.

Power Transmission Engineering is THE magazine of mechanical components. PTE is written for engineers and maintenance pros who specify, purchase and use gears, gear drives, bearings, motors, couplings, clutches, lubrication, seals and all other types of mechanical power transmission and motion control components.