Bonfiglioli Offers Mechatronic and Automation Solutions at SPS Nuremberg

Bonfiglioli is present at SPS Nuremberg from November 12-14. At Booth 450 in Hall 3A, Bonfiglioli showcases its comprehensive mechatronic proposal covering AMRs, material handling, logistics automation and packaging along with IIoT capabilities. Eyes also on electronics, with the solutions developed by Selcom.

AMR in motion

At the booth, visitors have the opportunity to see a Helko AMR in action, result of the cooperation between Bonfiglioli and Eureka System S.r.l. Helko is powered by Bonfiglioli’s motorized wheels and an electric drive in a tailormade approach.

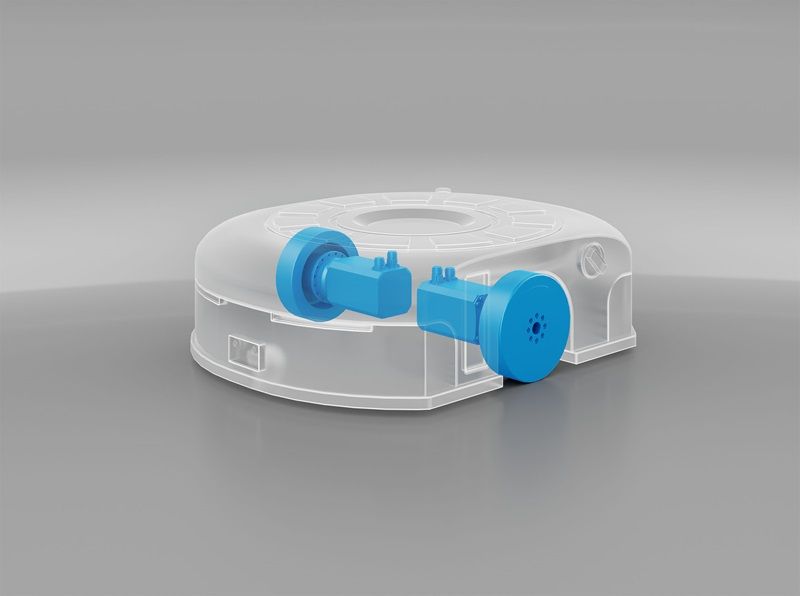

For the AMR and AGV market, Bonfiglioli has also developed the BlueRoll Platform, featuring a compact low voltage precision planetary gearmotor of the BMS Series, which is compatible with electronic drives including 24 or 48-volt batteries. The BMS Series offers compactness – it’s a unique piece without flanges - high torsional stiffness, and low moment of inertia, making it ideal for precision applications requiring accuracy and efficiency. With its space-saving design and range of options, the BMS Series boosts performance by combining the strengths of permanent magnets, synchronous low-voltage, three-phase alternating current motors and precision planetary gearboxes.

Bonfiglioli's expertise drives optimized material handling operations

For material handling, i.e. smart conveyors, three helical bevel gearmotors of the A Series are presented in the form of a demo, each of them with three different torque ranges – A10, A20 and A30, respectively coupled with the motors MXN, BSR and MX – and a sensorized DGM – MPM modular inverter. The systems showcased reflect the wide range of gears and motors made available by Bonfiglioli and the possibility to connect one single EDGE PC to several GMIs. The compact and worldwide certified IE3 MXN motor boasts a very high voltage range and is the best solution for automation application. The combination between the BSR highly efficient reluctance synchronous motor – free of rare earth elements and classified in the IE4 efficiency class - and the DGM decentralized inverter represents a plus capable of improving the energy efficiency and the TCO of machines and processes. MXN is one of the motors Bonfiglioli is focusing on the most (continuously updated and improved), it is set to eventually incorporate reluctance technology in the future. The system is completed by the Z-Sensor, which is directly connected to the inverter, without applying additional cables between inverter and PLC. This sensor enables the collection of on-site data which can be transmitted via a Profinet Fieldbus and forwarded with OPC-UA to Bonfiglioli’s IIoT system. The result is the continuous monitoring of the gearboxes with the aim of preventing any failure and malfunction of the entire system.