Software

Digital Transformation Drives the Future of Packaging

Expanding use of new and emerging technologies offers major opportunities to improve sustainability, efficiency, and production

Read More

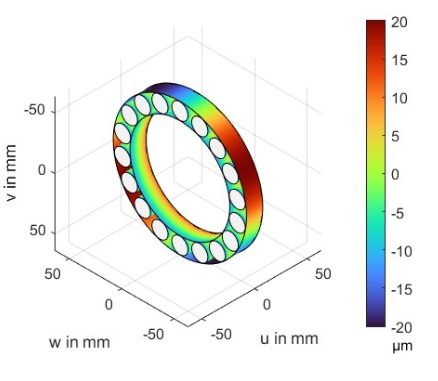

Repowering the Future: Data-Driven Wind Farms

Condition monitoring vital to future proof components and equipment in wind applications

Read More