Gearboxes

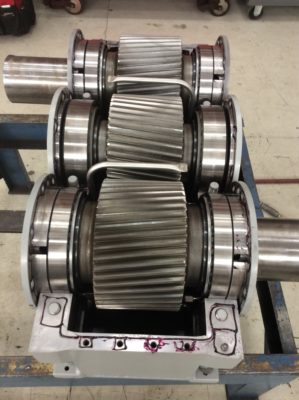

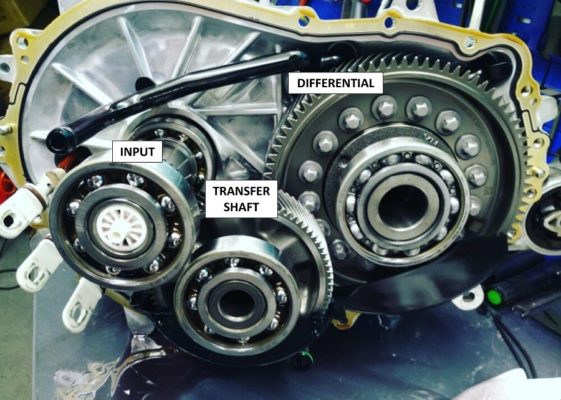

Paper Mill Precision

Atlanta Gear Works Offers Step-by-Step Process for Rebuilding a Beloit Differential

Read More

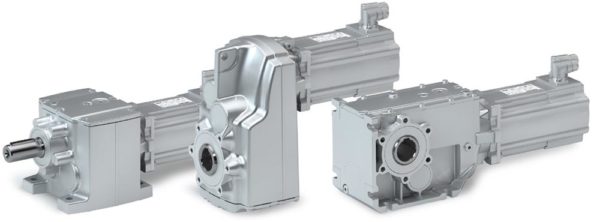

Advancing Technology for MRO

Sensors, drones, and software highlight latest condition monitoring tools for PT components.

Read More

KISSsoft Supports Student Racing Team in Poland

AGH Racing—Innovating and Designing Formula Student Vehicles

Read More