TCI Precision Metals A36 Carbon Steel Blanks Now Available Online

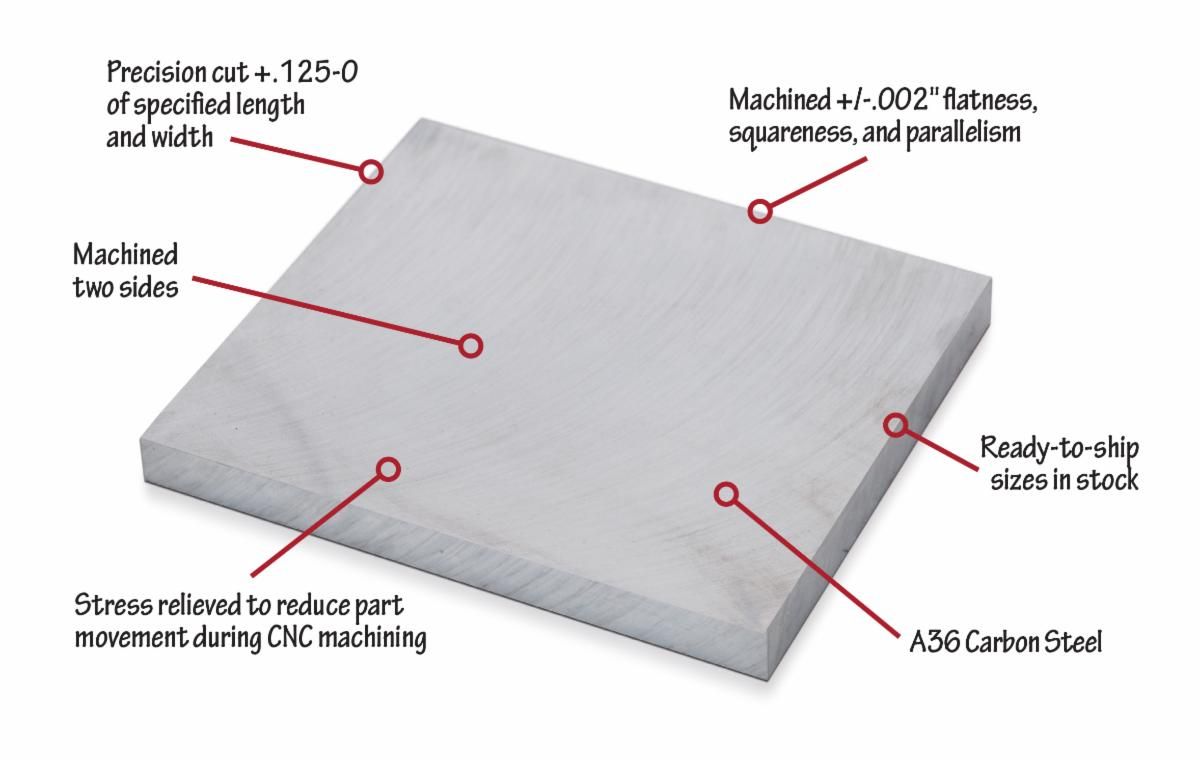

TCI Precision Metals announces that its A36 Carbon Steel, Ready-to-Ship blanks are now available from OnlineMetals.com, an e-commerce metal and plastics supplier. The pre-machined blanks allow customers to order flat, square, and parallel materials to close tolerance specifications.

ASTM A36 steel plate is a grade of steel commonly used in structural applications. This mild steel contains alloys that give it properties such as machinability, ductility, and strength that are ideal for building applications. Due to its high strength, many bridges and other structures are made with A36 steel. It is also used for components in automotive, heavy equipment, and oil and gas applications, including frames, bearing plates, tanks, gears, and base plates.

“A36 Ready to Ship Blanks help shops shorten setup time, reduce scrap, and increase overall throughput up to 25% or more by eliminating material prep. Blanks arrive machine-ready for production,” said Ben Belzer, president and CEO of TCI Precision Metals.

Precision blanks eliminate the need for in-house sawing, grinding, flattening, squaring operations, and outside processing. Blanks are consistent, part-to-part, which reduces setup time. In the case of flat blanks, the production process alleviates the material's residual stress, resulting in reduced part movement during finish machining. A36 Ready-to-Ship blanks are available in sizes ranging from .250”-2” thickness, 6” – 36” width, and 12” – 48” in length. Each blank is deburred, cleaned, and individually packaged to avoid damage during shipping. Ready-to-Ship Blanks arrive square, flat, and parallel within ± .002” of specified thickness and +.125-0 of specified length and width.

“At OnlineMetals.com, we specialize in cut-to-size, small to medium quantity orders shipped direct to any location. Pre-machined A36 carbon steel blanks that are Ready-to-Ship provide that extra processing value that lets customers order materials that arrive ready to go directly from receiving to machining. Customers can use the time they previously spent in setup and prep for more productive use of CNC machining centers,” said Matt Holzhauer, marketplace manager at OnlineMetals.com