Tecnofirma Develops Modular System for Electric Motor Production

Electric drives often need to operate under high voltages up to 800 V to provide more power and higher speeds. However, the risk of partial discharges increases at these voltages. In combination with high operating temperatures, these can locally damage the insulation and lead to machine failure. However, a good impregnation ensures not only electric insulation but also copper bonding, to mechanically strengthen the electric motor, and air gap filling, to allow a better heat transfer. In turn, the more accurate the impregnation of the electrical winding, the higher the overall performance, coil insulation and voltage resistance, which has a positive effect on the service life of the drive train. For this reason, Tecnofirma S.p.A. has developed a modular impregnation system that, thanks to its design, makes it possible to achieve much better filling of the wire packs in the stator than comparable trickling variants while consuming less resin. By tilting the component at an angle of 5 to 10 degrees, the resin reaches the cavities faster and more homogeneously. Thanks to NC-controlled impregnation axes that can be programmed in all traversable directions (x-y-z) with an accuracy of up to 0.1 mm, a high degree of reproducibility is ensured even with different component geometries.

An electric motor is only as good as its insulation: If the individual windings and the cavities between the wires are insufficiently impregnated, wear is more likely, and the risk of partial discharges increases. If a phase failure occurs, for example, the windings of the two other phases must conduct more current. This results in excessive heat generation to the detriment of motor train performance. Furthermore, such partial discharges can occur over a long period of time without being noticed, leading to a creeping failure of the motor.

"Impregnation basically pursues two goals: On the one hand, the voids in the stator winding are closed by allowing the resin to penetrate by capillary action. On the other hand, the wire heads are covered at the end so that undesirable voltage contacts cannot occur," explains Omid Armaghan, managing director of Tecnofirma Deutschland GmbH. "Here, it is important to keep the resin, which by nature tends to slip, in the desired position until the firing process is completed." Impurities as well as air bubbles must be excluded, while at the same time perfect saturation of the die in the sheet package must be produced. This makes the process extremely complex and very demanding, especially when it comes to handling the resin. To make the process more efficient and safer in terms of insulation quality, Tecnofirma equipment experts have developed a modular system that perfectly coordinates all the relevant process parameters: Correct positioning of the nozzles, precise control of the amount of resin dispensed, optimum temperatures of both the resins and the stators, and more flexible positioning of the components via rotation speed, direction of rotation and inclination.

Although the impregnation system was designed as a stand-alone module, it offers numerous possibilities for connection and interlinking. For example, it can be integrated into a powder coating process or coupled to preheating or cooling stations.

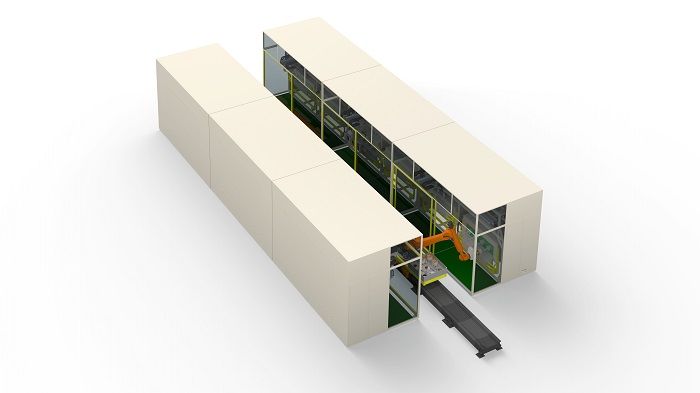

Although the impregnation system was designed as a stand-alone module, it offers numerous possibilities for connection and interlinking. For example, it can be integrated into a powder coating process or coupled to preheating or cooling stations. The impregnation system was designed as an independent module consisting of two ovens arranged side by side. These are equipped with chucks for the stators and all the mechanics for operation, i.e., servomotors, heating and fans. "The two ovens share an axis system on which the resin metering and the application group for the trickling process are installed," says Armaghan, describing the setup. "We can program the axis movements down to 0.1 mm in all traversable directions (x-y-z). Precise positioning as well as monitoring of the last positions via camera ensures that the nozzles always step into the exact position." The components are slightly tilted during impregnation, which increases the filling factor. This allows a much more homogeneous resin distribution to be achieved.

In addition, the system design increases the efficiency of the insulation process, as work can be carried out in parallel on two ovens. By combining impregnation and gelation, production volumes can be increased. In the first unit, the impregnation process takes place with the rotating chucks leaving the oven and moving forward to facilitate access to the nozzles. Meanwhile, the gelation of the previously completed impregnation takes place in the other oven. Tecnofirma attaches great importance to constant optimal tempering of both the resin and the components. Stators are maintained at the right temperature during the entire course of the trickling application, which is particularly advantageous for long stators cores with longer impregnation time. "We are currently conducting studies in which we feed the thermal energy stored in the process exhaust air back into the system. Currently, we are using some of it to circulate heat into the curing oven," Armaghan said. “In addition, we use a special technology in our furnaces, such as the ‘canopy’ architecture, which minimizes heat distribution - and thus optimizes energy consumption.”

Flexible module allows easy process connection and maintenance.