NKE Set to Display Bearings at Husum Wind 2023

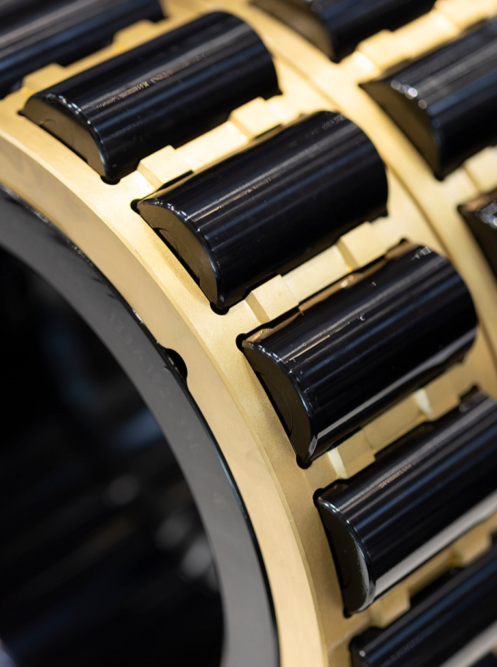

The black oxide coating forms a protective layer on the functional surfaces of the bearing and ensures, among others, improved operating and wear characteristics.

NKE Austria GmbH (Booth #3C16) will exhibit at this year's Husum Wind trade show taking place September 12-15 in Husum, Germany. The Austrian bearing manufacturer participates for the first time at the fair for renewable energies in Northern Germany.

For wind turbine gearboxes and generators, NKE offers the complete range including cylindrical roller bearings, tapered roller bearings, spherical roller bearings, four-point contact bearings, deep groove ball bearings, electrically insulated rolling bearings, hybrid bearings and special bearings. NKE’s product range for wind power is complemented by plain bearings from Swiss manufacturer Kugler Bimetal – the two companies recently established a strategic partnership to expand their portfolio especially for the wind market.

“Wind turbines run under difficult and demanding operating conditions,” says Michael Schöffmann-Rössl, head of application engineering at NKE in Steyr, Austria. “The bearings used must operate extremely efficiently and offer the greatest possible reliability. NKE has a proven track record. We have been supplying OEM companies with high-quality bearings for over 20 years. Bearings from NKE have been installed in over 4,500 turbines across Europe, the USA and China.”

For applications, Schöffmann-Rössl gives some examples: “Bearings from NKE are used in all bearing applications of an Envision gearbox: from the carrier, that is the rotor side and generator side, to intermediate and planetary shafts, to high-speed shafts. Additionally, we have designed bearings with improved profiles and contact pressure, which we develop specifically for high-speed shafts in close cooperation with the customers' technical teams. We also have designed new bearings with power density technology, which are only 20 percent larger than conventional bearings but deliver twice the energy. This enables optimized wind turbine performance and maximum energy recovery from the airflow.”

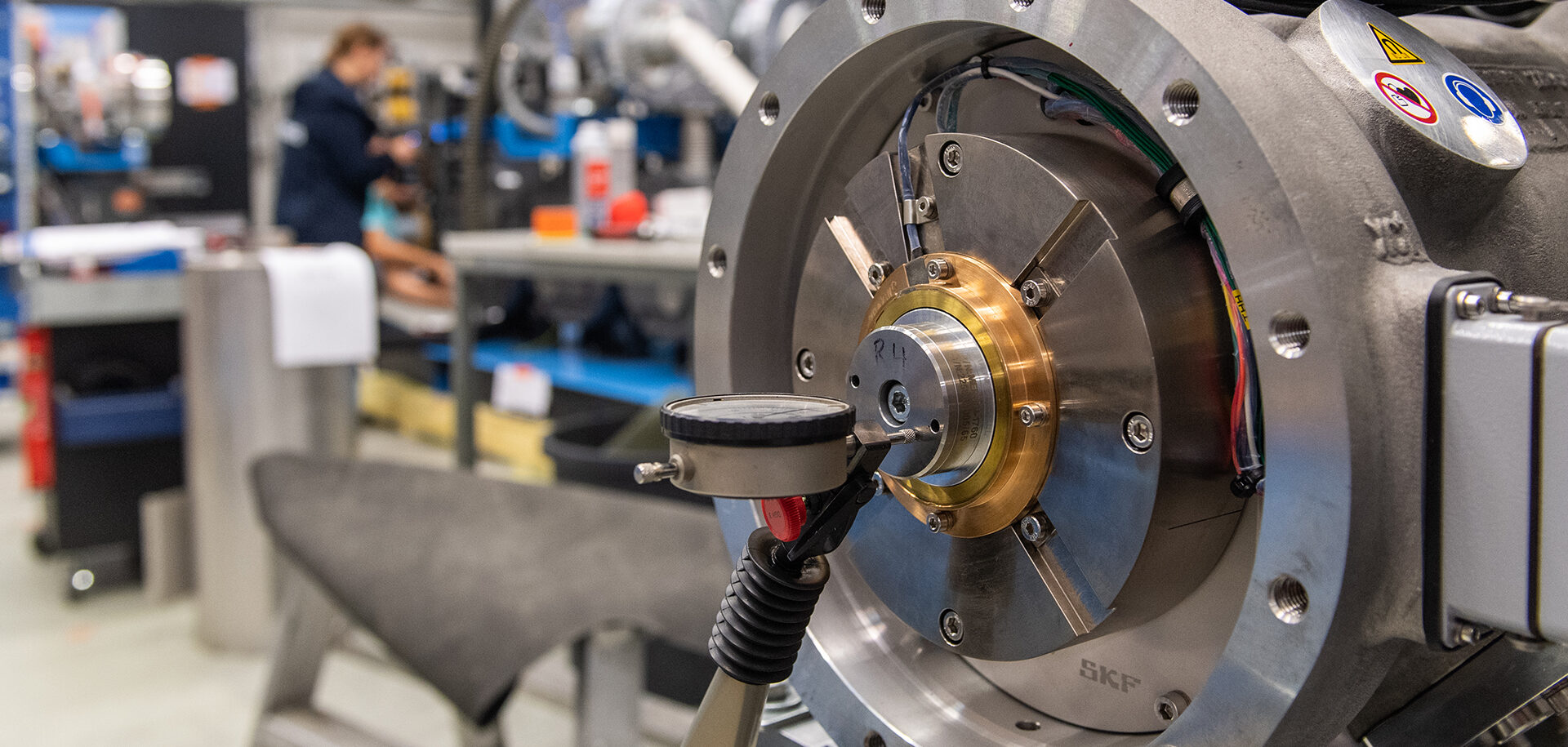

At the company headquarters in Steyr, NKE has established a competency center for large size bearings, including state-of-the-art manufacturing facilities and a logistics center. All NKE bearings undergo strict, documented quality control procedures. In addition to comprehensive technical consulting services, NKE’s application engineering department offers support for obtaining certification to wind standards such as GL2010, IEC61400 or individual customer specifications.

Related Articles

-

December 11, 2024

-

Power Density Progress

December 2, 2024 -

CCTY Tackles Humanoid and Industrial Robot Development

September 13, 2024

-

The Future of Power Manufacturing, Warehousing, and Logistics

October 28, 2024 -

5 Ways to Save Money Through Ultrasonic Analysis

December 11, 2024

-

The Future of Power Manufacturing, Warehousing, and Logistics

October 28, 2024 -

5 Ways to Save Money Through Ultrasonic Analysis

December 11, 2024 -

Operational Improvements

December 11, 2024