Carlyle Johnson Offers Multiple Disc Pulley Clutch

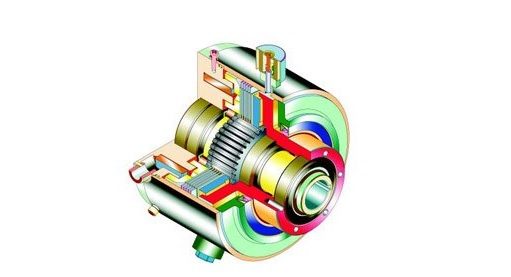

Gasoline engines, pumps, generators and other machines operating in rugged environments require long-lasting components to ensure successful performance. Clutches designed with durable materials can prevent breakdowns, which would otherwise lead to expensive maintenance and downtime. One example of a ruggedized clutch — the Carlyle Johnson's EPC multiple disc electric pulley clutch — consists of a standard electromagnetic multiple disc design and utilizes oil shear to enhance service life.

Oil Shear Design Improves Operating Temperature

As the pulley clutch engages, lubricating oil squeezes out from between the friction discs and shears across the friction surface, transmitting the engagement torque. This process significantly reduces heat along the friction disc surface. Increasing heat dissipation, the heated oil is also forced to the outside of the housing.

Hassle-free Mounting

You can mount an EPC clutch in a matter of minutes. Ideal for devices where the clutch is routinely disengaged from the main power source, the EPC excels in applications like gasoline engines, pumps, generators, conveyors and gearboxes.

Excellent Protection

The EPC clutch thrives in harsh applications and provides a long lifespan due to its unique oil shear multiple disc design. Its fully sealed housing allows the clutch to operate in a bath of Type A automatic transmission fluid, increasing protection from damage due to environmental conditions, as well as washdowns.

Standard Features

Torque ranges: 15-300 pound-feet.

Standard operating voltages: 6-240 VDC.

Self-adjusting multiple disc units.

Fully enclosed, durable housing.

More than ten times greater life expectancy than single-plate, dry clutches.

Customize Your Clutch

If one of our standard models doesn’t meet your exact specifications, Ringfeder will modify their EPC pulley clutches.

cjmco.com/products/electric-clutches/pulley-clutch-epc.shtml