KISSsoft Applies Raceway Modifications for Rolling Bearings

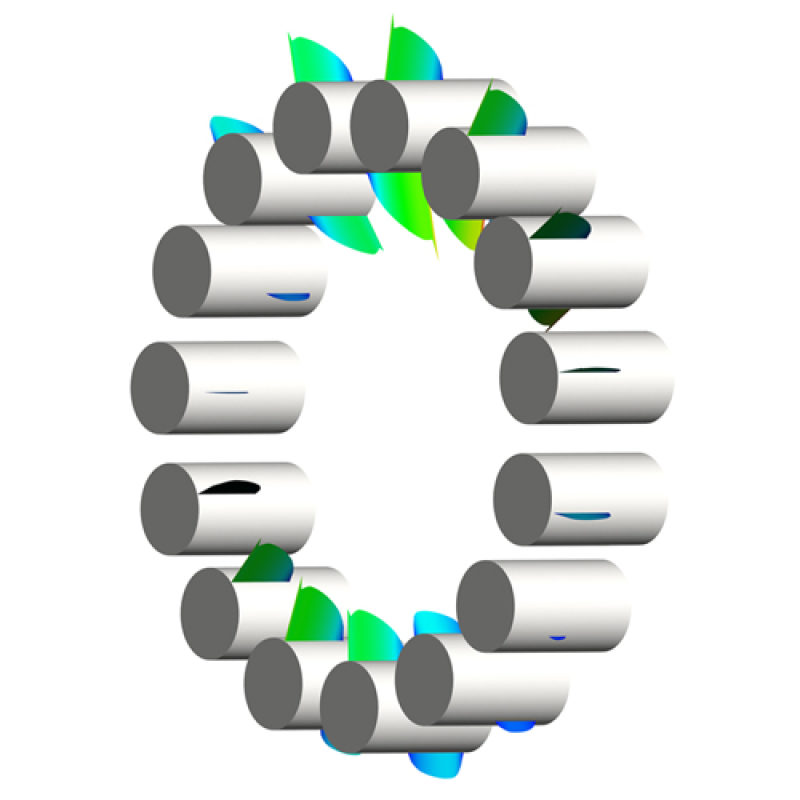

Rolling bearing life depends on the contact stresses that occur between the rolling elements and the raceways. Contact stresses are calculated from contact loads, which in turn depend on the external loads acting on the bearing and the precise internal geometry of the bearing.

In case of roller bearings, contact conditions highly depend on the distribution of the contact stresses along the length of the rollers, which is typically controlled via rolling element modifications. However, another possibility to control the distribution of the contact stresses is by applying modifications to the raceways.

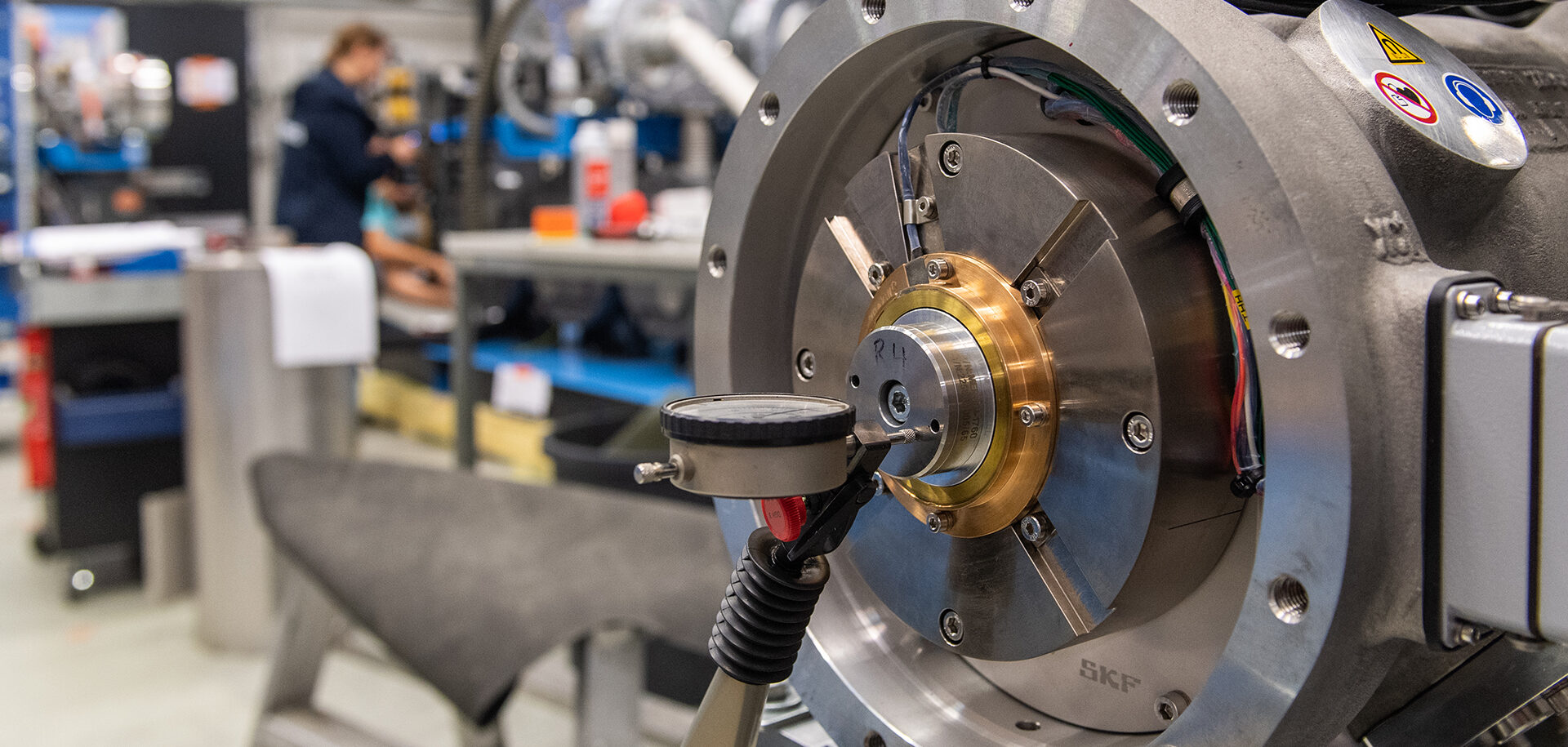

The application of raceway modifications can be especially useful, when one must deal with manufacturing deviations or assembly misalignments found out during the final control or assembly. In such cases, it might be rather expensive to get a completely new bearing with properly modified rolling elements. Alternatively, the raceways can be ground to achieve better stress distribution. In this case, an engineer can use KISSsoft to design the best possible raceway modifications under the given circumstances and simulate the effect of these modifications.

Raceway modifications can be applied to cylindrical roller bearings as of the KISSsoft Release 2022. In the future, the possibility will also be added to the other types of rolling bearings.