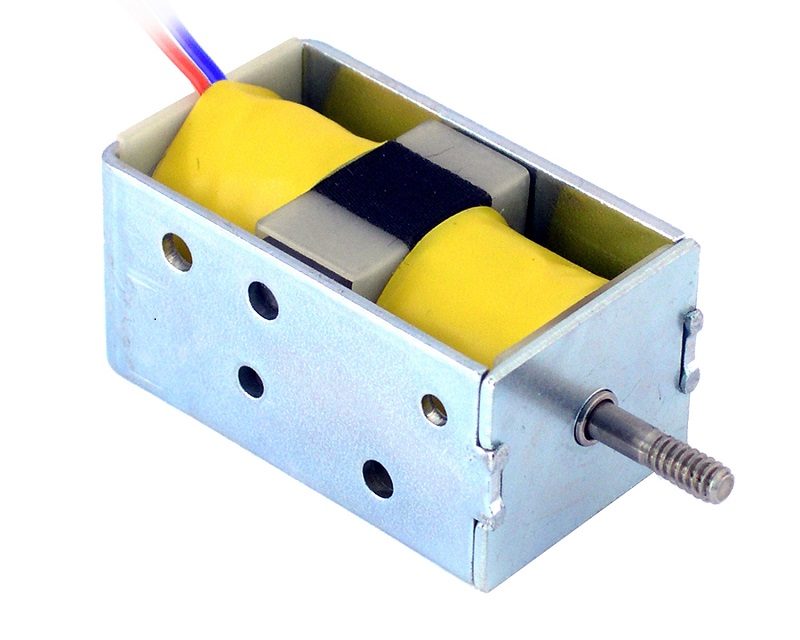

MSS Offers Bi-Directional Latching Solenoids

Latching Bi-Directional Solenoids released by Magnetic Sensor Systems (MSS) are low cost, economical to use, and easy to integrate into an application. The S-18-100LC2 and S-18-100LF2 Latching Bi-Directional Solenoids feature the same compact dimensions: 1.00 in. wide x 0.84 in. high x 1.73 in. long with 6-32 threaded Push/Pull plungers. The plungers have a travel of 0.19 in. and in the extended position are 0.50 in. long, two 8-32 (or optional M4) threaded mounting holes are located on the underside of the solenoids.

In a latching solenoid the push/pull force is the result of momentarily energizing the coils and the latching is by permanent magnets. A change of the stroke direction can be achieved by reversing the polarity of the energizing current.

An application will dictate the selection of either an S-18-100LC2 or S-18-100LF2 solenoid. The “C” in the S-18-100LC2 indicates the plunger ends and the mating stops are conical shaped, whereas “F” in the S-18-100LF2 indicates the shape of the plunger ends and stops as flat. The difference is realized when the two coils of the solenoids, connected in parallel, are supplied with 7.5 watts of power. The conical ends and mating stops of the S-18-100LC2 have a lower latching force (1.4 lb.) and a higher push/pull force (0.5 lb.) in comparison to the S-18-100LF2 with its high latching force (5 lb.) and lower push/pull force (0.3 lb.) Typical applications include valve control, office equipment, switch activation, clamping, positioning, games and toys, vending machines, and door locks.