KISSsoft Integrates Schaeffler Catalog Bearings

Manufacturer-independent engineering tools, such as KISSsoft, basically offer users the opportunity to offer more flexibility in selecting suppliers and procuring components. On the other hand, in some cases there is no access to exclusive product data from the manufacturer in order to be able to perform the calculation with the greatest possible accuracy and reliability.

In the meantime, hybrid software solutions have also become established on the market, in which the original manufacturer data - not visible to the customer - is integrated into the software: KISSsoft is one of these.

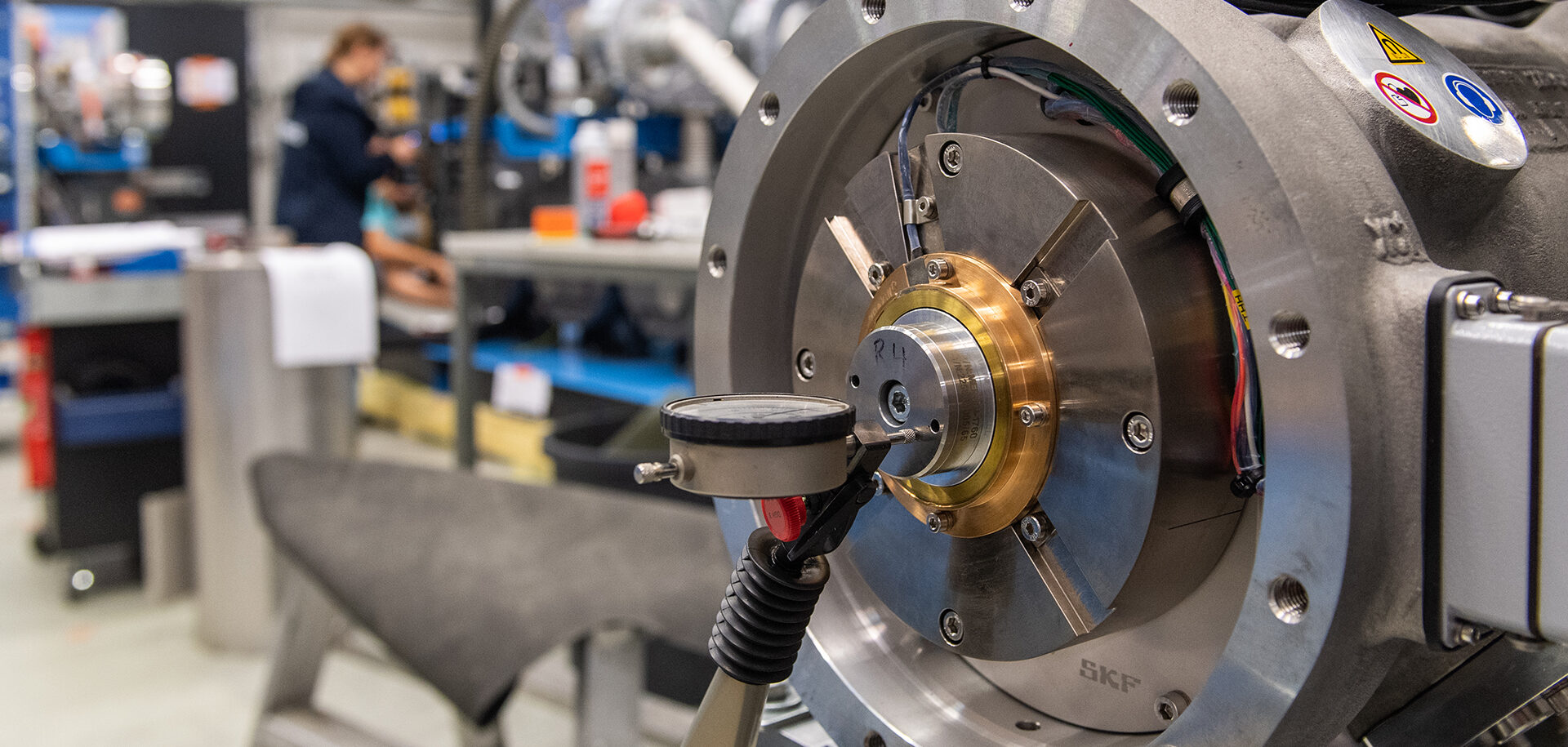

For rolling bearing calculations, catalog bearings from Schaeffler can now be selected in KISSsoft with the manufacturer data stored invisibly. These standard bearings are calculated using the manufacturer's real internal geometrical data. One of the many advantages: In addition to the calculated rating life, for example, the load distribution in the bearing and the pressure curves for each individual rolling contact can be determined very precisely and displayed graphically.

Users thus benefit from greater accuracy and reliability of the calculation. It is now also possible to make comparisons very easily with rolling bearings from other manufacturers with regard to the effects of the internal design.