ZF Wind and R&D Test Systems Develop Test Bench for Powertrains and Gearboxes

In its largest order to date, Danish wind turbine test specialist R&D Test Systems will develop the 30 MW powertrain and gearbox test bench for ZF Wind Power’s future “Test & Prototype Center” at Lommel, Belgium. Capable of simulating the multiplicity of wind loads that a nacelle powertrain might experience in its lifetime, the test rig, to be delivered in 2024, will help improve product reliability and shorten time to market.

Dimension facts of the new back-to-back powertrain and gearbox test rig:

- 45 million Nm is like one car on a 3 km wooden stick

- 200 concrete trucks will pour in the concrete of the main foundation

- A crane with 300-ton lifting capacity can also lift 50 African elephants simultaneously

- The length of the powertrain and gearbox test rig at 60 meters is more than the length of three tennis courts

“The wind loads, and directions can vary greatly, and each change creates loading on the nacelle powertrain,” says Ralf Nieschler, key account manager, R&D Test Systems. “This new test rig must be much more powerful than the powertrain it tests, providing proof that the next generation of offshore turbines of, say, 20 MW are capable of operating reliably in extreme offshore conditions over the defined lifetime,” he adds.

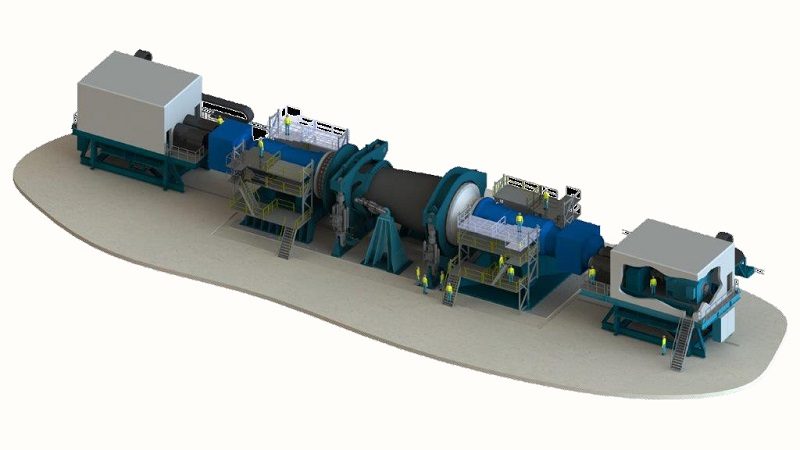

With its two 30 MW motors, the test rig will be the world’s most powerful powertrain and gearbox test bench and, at 60-meters long, also the largest.

“The force of gusts wind can be a bit like a herd of elephants, pushing the blade around. This twisting and bending of the powertrain in all possible directions in the test rig will simulate the effect of 20 years of wind conditions in just a few months,” adds Nieschler.

Nacelle components tested in parallel

The test rig employs the company’s “back-to-back” concept, where two nacelle components – for example two powertrains or two gearboxes- are tested simultaneously, leading to significant time savings.

Performing high-torque twisting, the 30 MW motors are positioned on each end of the nacelle components under test. Additionally, a specially designed load unit is located between the nacelle components and provides the wind loads needed to simulate the varying real-world conditions. Together the motors and the load unit can simulate not only the harshest loads of wind but also the effect of wind coming from different directions.

Despite weighing 5,700 tons and with a drive torque of 45 million Nm – equivalent to the load of 30 family cars dangling from the end of a 100-meter turbine blade – and a bending moment of up to 64 million Nm, the test rig can cope with test components of varying dimensions.

The test rig will be developed at R&D Test Systems’ headquarters in Denmark. In addition to electrical, systems, software and mechanical engineers, the project will draw on civil engineering expertise for the reinforced concrete foundation that needs to be strong enough to withstand the extreme fatigue and ultimate wind loads during tests as well as the powertrain itself that can weigh several hundred tons.

A team of 35 full-time engineers have already started work on the test rig together with international specialist suppliers. The test rig will be transported as individual modules to Belgium. The project makes use of R&D Test Systems’ in-house software development team which will create tools for the analysis of the test data. Also, part of the project is a crane with a lifting capacity of 300 tons for mounting of test powertrains into the rig.

Highly accelerated lifetime testing (HALT) experience applied

R&D Test Systems’ experiences in highly accelerated lifetime testing (HALT), where wind turbine prototypes are exposed to the equivalent of 20 years of weather conditions in a few months to discover the physical limitations of a design and ascertain product reliability.

“To be awarded with a project of this size to develop the world’s most powerful powertrain test rig for wind turbines is a recognition of R&D Test Systems’ proven development expertise in specialized, large-scale and powerful test rigs in the wind power industry,” says Peter Ulrikkeholm, CEO of R&D Test Systems.