The Flexibility Factor

A Closer Look at Huco Oldham Coupling Customization

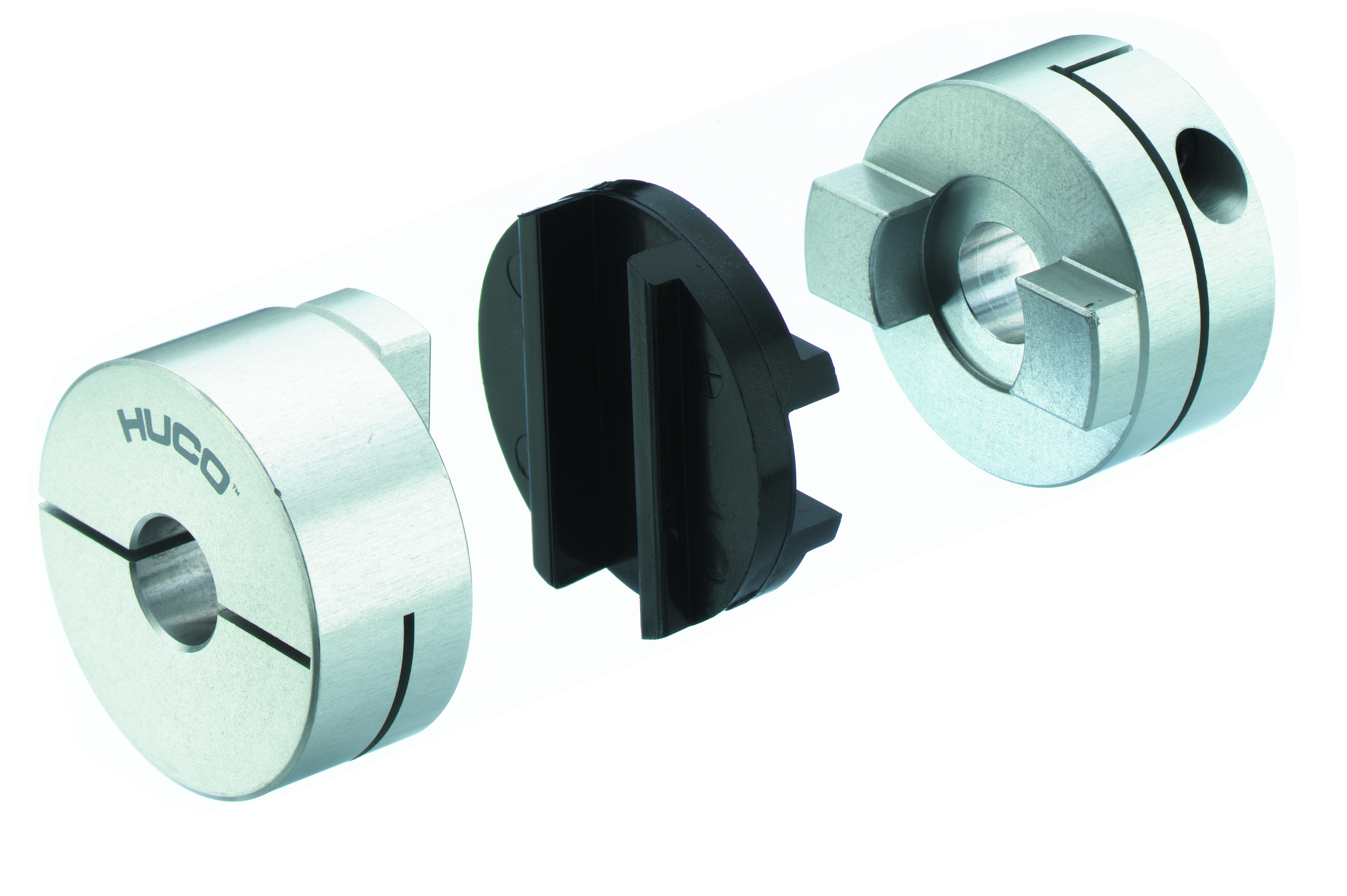

Exploded version of the Oldham coupling.

A flagship coupling in the Huco range, the Oldham solves the problem of side forces due to misalignment. Misalignment couplings that bend or flex do cause some side loading on bearings and shafts as the coupling tries to spring back. Of course, over prolonged use this can result in rapid deterioration of bearings, extra load on the motor, and eventual coupling fatigue.

The Oldham coupling design accommodates misalignment by allowing sliding between metal hubs and a plastic disc so not to create any lateral forces. This effectively protects equipment from the side loads, improving reliability. Discs are made from engineering plastics and are replaceable and interchangeable for different properties. Standard discs are Acetal, for strength, but Nylon discs can also be chosen for resilience, or damping properties. PEEK discs are sometimes chosen to insulate against electric current leakage or heat transfer. Furthermore, the disc can provide overload protection, as it will break under extreme load to protect associated equipment. The Oldham’s three-piece construction allows easy assembly and installation too. While a general-purpose coupling, the Oldham is particularly suited for use in stepper driven positioning, as it handles high torques while still delivering high accuracy.

“Various available Oldham coupling disc materials provide users with the flexibility to tailor a coupling to meet their specific application requirements,” said David Lockett, Huco managing director.

Capping and filling machine (courtesy of Cap Coder).

Capping and filling machine (courtesy of Cap Coder).

Custom Demands

The precision applications that Huco’s couplings are designed to fit demand a high level of specialization. The design of a motion systems in, for example, medical devices or food production lines varies greatly, so a ‘one size fits all’ approach isn’t optimal for precision couplings. The coupling may have to fit a predetermined shaft size or operate within the constraints of existing device packaging. To meet this need, Huco can extensively customize couplings to meet unique requirements.

Huco can design and deliver custom Beam, Bellows and Oldham couplings to fit shafts from <1 up to 50 millimeters in diameter. Designed to provide couplings in low volumes to support prototyping, testing or small production runs, customers can expect the design process to be complete in a few days and orders produced and delivered within 10 working days.

Cochran engineers selected Oldham couplings from Huco to meet its burner performance specifications.

Cochran engineers selected Oldham couplings from Huco to meet its burner performance specifications.The service is enabled thanks to a high-tech lean manufacturing facility which allows custom designs to be realized quickly. This also means that Oldham and Beam couplings can be machined onto custom shafts as a complete assembly. Injection molding and 3D printing are also available to produce unique components.

Different coupling designs accommodate misalignment in different ways. Huco’s standard range of couplings offers design engineers a wide range of solutions to accommodate it, along with consistent zero-backlash capabilities, to safeguard the reliability of associated equipment.

However, when it comes to specifying couplings for precise machinery, a standard coupling will not always provide the specialization that is often required.

“For engineers requiring a single coupling, machine builders building and testing a new prototype or device makers starting a production run—an off-the-shelf item may not provide an optimal solution to secure reliability and performance,” Lockett said.

“To serve these specialized devices and machines, Huco has built a global customization service based on a proven range of standard couplings,” Lockett explained. “Our extensive in-house capability means that custom solutions can be delivered efficiently, exactly to specification. Ultimately, we’ve found that providing couplings for precision applications is anything but standard.”

Couplings with zero-backlash were needed to support Cochran's burner models.

Couplings with zero-backlash were needed to support Cochran's burner models.

Cap Coder, a British manufacturer of standard and custom capping, filling, labelling and coding machines, needed precision couplings for use on its equipment. The couplings connect the drive motor to the torque capping heads on low-to-medium volume filling and capping machines utilized by beverage and pharmaceutical customers.

Positioned within the main capping torque head, the coupling is considered one of the machine’s most critical components as it reliably and repeatedly transfers power, while maintaining position and controlling the applied torque to the container cap.

After a review of available alternatives, Cap Coder chose to install Huco Oldham couplings on all capping head assemblies incorporated on its various machines. Oldham style couplings were selected due to their precision and reliability. Cap Coder has not had a Huco coupling failure on any of its machines that have been in service less than five years, many operating on 24/7 production schedules.

Since introduction of the Huco Oldham coupling, Cap Coder has not had a coupling failure on any of its machines.

Since introduction of the Huco Oldham coupling, Cap Coder has not had a coupling failure on any of its machines.The Oldham coupling design transmits torque through a central disc that slides over tenons on the hubs under controlled preload conditions. To meet the capping torque head requirements, Huco supplies complete three-part Size 33 Oldham couplings comprised of two aluminum clamp-style blind hubs and an acetal disc that provides high torsional stiffness and long backlash-free life. The 1.31 in. (33.3 mm) dia. couplings feature a 79.7 in lb. (9 Nm) peak torque rating.

“Precision couplings are essential for transmitting power to the capping head and maintaining position control,” said John Walsh, sales director at Cap Coder. “The Oldham coupling provides us with both precision and reliability in application. The performance of the coupling as part of our CC720 Mk IV capping head has been more than satisfactory.”

He continued, “The Oldham is now featured in all capping heads that we produce, becoming a part of every capping and filling machine in our range. This decision has been vindicated, as we have never experienced a coupling failure on one of our machines that is less than five years old.”

Cochran, Ltd. is a global designer and manufacturer of industrial boilers and burners. The company needed reliable precision couplings for use on its range of combustion burners. The couplings are fitted between air servomotors and dampers on most burners. On some burner models the couplings are installed between gas servomotors and butterfly valves.

Various coupling solutions were explored. However, most couplings did not offer the precision required and suffered backlash and eventual failure resulting in poor combustion and excessive emissions.

Ultimately, Cochran engineers selected Oldham couplings from Huco to meet its burner performance specifications. The precision engineered Huco couplings provide stable movement with no backlash throughout the actuated range. This results in reliable combustion and reduced emissions.

Huco supplies complete three-part Size 41 Oldham couplings to meet the requirements of most Cochran burner models. The through bore couplings are comprised of two aluminum clamp-style hubs and an acetal disc that provides high torsional stiffness and long, backlash-free life. The 1.62 in. (41.3 mm) OD couplings feature a 151 in.lb. (17 Nm) peak torque rating.

altramotion.com/en/our-brands/huco

Learn more about the history of the Oldham coupling here:

powertransmission.com/articles/225-john-oldham-the-coupling-personified