Hannover Messe USA - What we Learned

Hannover Messe USA: What We Learned

IMTS 2018 had its fair share of machine tools, 3D printers and advanced robotics. Meanwhile, the East Hall — home to Hannover Messe USA — took a more systematic approach, highlighting the smart components and techniques that will be integral in developing the digital factory of the future. Motion control, automation and mechatronics will each play a crucial role particularly as more and more industrial processes become digital. Here are some immediate takeaways from our time spent at Hannover Messe USA:

Industry Innovators are Leading the Way

Companies like Siemens and ABB (B&R Automation) are offering a variety of tools, controls and automation capabilities to improve areas in everything from material handling and packaging to milling gear generation and software.

Case in point: A Siemens booth tour highlighted how shop floor machines will be operated, managed, programmed and maintained in the future. The full process chain — from CAD to CAM to virtual simulation and onto production — gave visitors a sneak peek into life as an engineer in 15 to 20 years.

B&R Automation announced a new communication protocol during the show that will allow all production process data to be transferred using a single protocol. The X20BC008U bus controller functions as an OPC UA server and provides all information about connected I/O modules to OPC UA clients from any manufacturer. This includes, for example, controllers, SCADA systems, ERP systems or cloud applications. It essentially eliminates interfaces, gateways and the associated loss of information that occurred in the past.

A Systematic Endeavor

Mechanical, electrical and computer engineering (your basic mechatronics platform) continues to work its way into our industry. Companies are no longer looking at a single component or focusing on one product that they’ve been selling for years. Digital factory solutions require a systematic approach and companies like Lenze America are taking the lead in this area.

“We’re looking at everything these days beyond just the components,” said Ralph Rosa, president at Lenze America. “We have the electrical, the mechanical, the drive controlling the speed, the data available in the cloud. In between, we do motion control for the robotics and our PLCs handle the automation. Basically, a company that started in 1947 with geared motors has become a complete solutions provider. It’s a pretty exciting time to be involved in these areas.”

Complex Material Handling Systems

SEW Eurodrive displayed its mechatronic drive system including the MoviGear Series where motors, gear units and electronics come together to offer a simplified engineering solution. The MoviGear Series offers a high level of system efficiency, which in turn helps lower the energy costs. The integration and coordination of all the drive components leads to a long service life and high system availability. Shaun Millington, systems engineer, discussed how these intelligent devices reduce the startup time and support the monitoring and maintenance tasks. Drive tasks can be solved quickly and easily using corresponding application software.

The housing has been optimized specifically for these types of applications and can be easily integrated in today’s conveyor systems. It also enables new developments to be implemented from a completely new perspective. This technology masters high break-away and acceleration torque levels after longer system downtimes time without any limitations. The power required to drive the system can be reduced significantly.

There’s a Solution for That

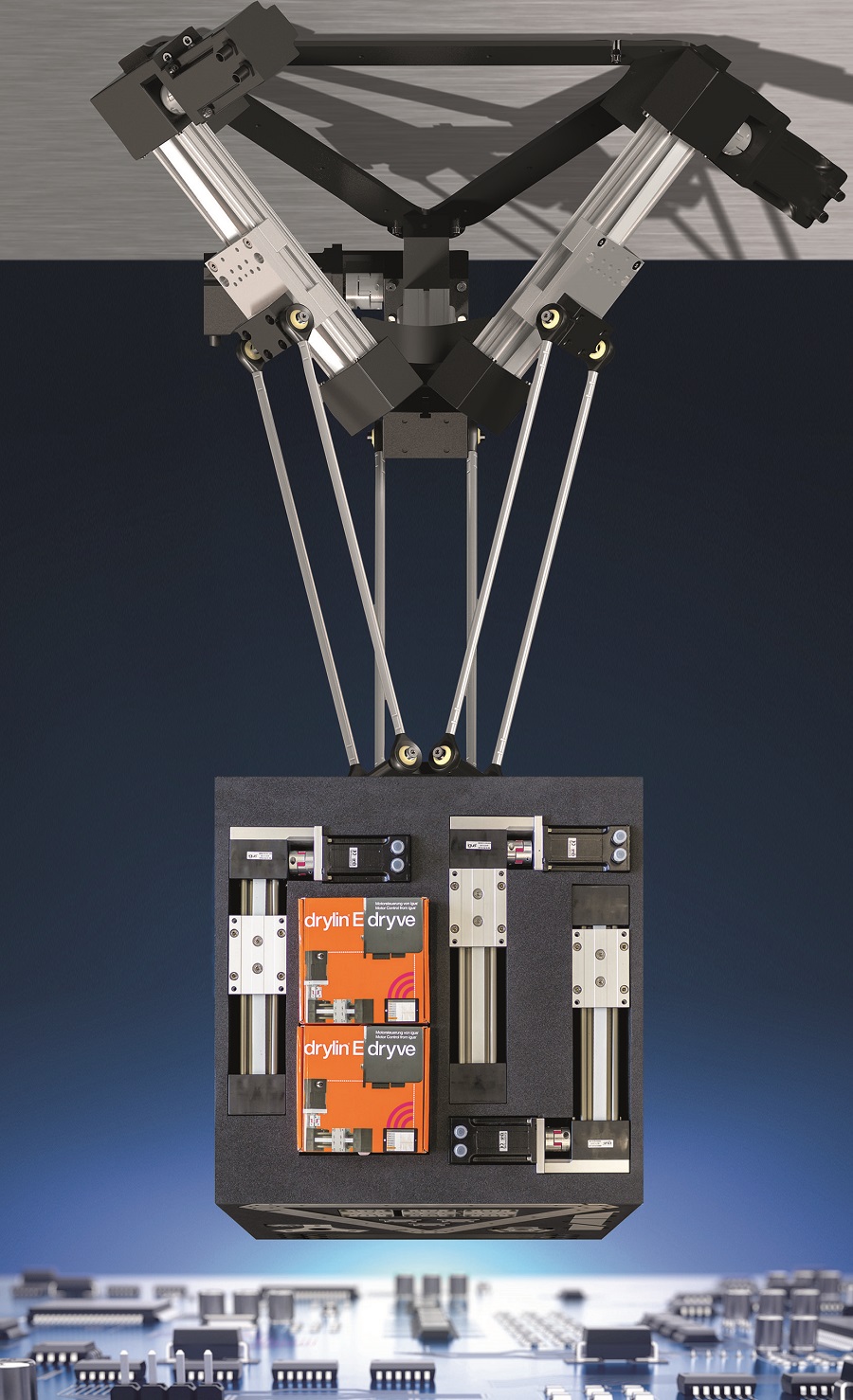

Igus is getting creative with its product offerings in 2018. The company recently introduced a low-cost, delta robot solution for automation needs. This delta robot includes a maintenance-free toothed belt drive, encoders, stepper motors and optional drive controllers. Chris Dennen at Igus believes the low price point and easy installation gives Igus a unique solution for assembly functions, pick and place tasks and inspection applications.

“The cost-effective delta robot enables our customers to have their own control box and integration at a cost of less than $9,000,’’ said Matt Mowry, Igus’ U.S. drylin product manager. “They pay off after just a few months, a maximum of half a year.”

Other interesting news from the Igus booth is how the company continues to find ways to tie its variety of products together to create new automation and shop floor solutions such as combining its cable and chain products with its linear guides to create customized solutions.

Real Time Monitoring

While we’ve reported plenty of information on bearing and motor monitoring practices in the PT industry, the trend for more sensors and more data collection is indeed expanding to all of the components found in the pages of PTE.

Bruce Gretz, executive vice president at Steinmeyer, discussed the monitoring of ball screws during the show. “Steinmeyer is utilizing sensors to detect the wear of critical machine components in order to collect data to reduce downtime and optimize a maintenance plan,” Gretz said.

With these capabilities, Steinmeyer can detect component issues at an earlier stage and order the necessary maintenance in a timely fashion. The company is also working with IFM, a sensor specialist, to develop a system for the status monitoring of ball screws.

IMTS: By the Numbers

This record-breaking event — 129,415 trade show registrations, 2,563 exhibitors and 2,123 booths — proved that digital technology, automation and additive manufacturing are driving interest in manufacturing technology. You were hard-pressed to walk any of the McCormick Place Halls last week and not find SOLD signs on several machines or see smiles on the faces of sales personnel. The word is out that the technology available today will better prepare manufacturers to conduct business in the years to come.

According to Peter Eelman, vice president, exhibitions and business development at AMT, IMTS 2018 set records because “manufacturing technology has grown exponentially since the last show. The booming manufacturing economy means visitors have capital and are ready to invest.”

The Conversation Continues

Hannover Messe is driving forward the digital transformation of the production and energy industries. Every year marks the next step into the future. For 2019, the guiding theme is “Integrated Industry — Industrial Intelligence,” for the show in Germany where digital networking between humans and machines in the age of artificial intelligence will be examined. Read upcoming issues of PTE to learn more about the components and systems featured at Hannover Messe USA 2018.