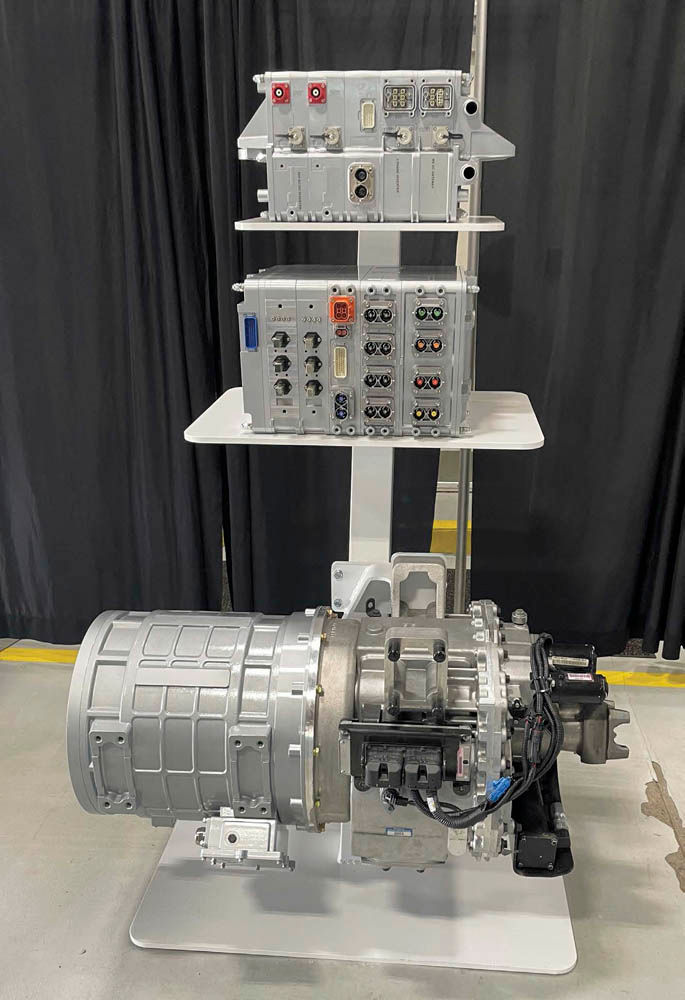

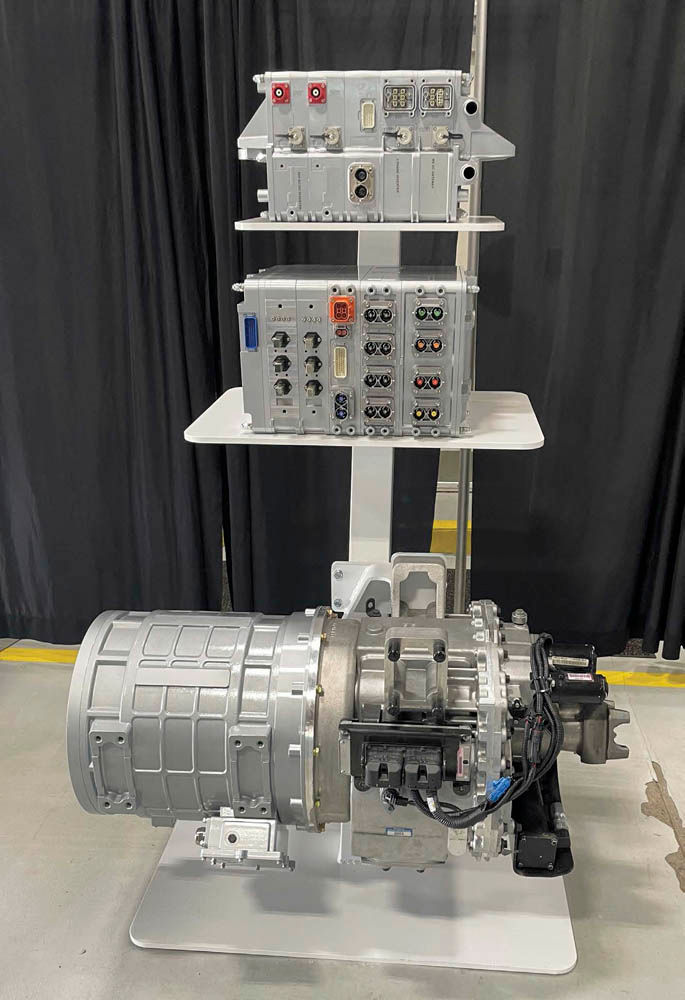

Developed to aid efficiency, Eaton’s purpose-built medium-duty and heavy-duty EV transmission helps to increase range, grade capability and acceleration for commercial electric vehicles. Leveraging decades of experience, this EV transmission is based on proven, robust and efficient layshaft architecture and allows for use of a smaller motor.

Eaton’s new 4-speed transmissions provide superior performance on grades and acceleration for electrified commercial vehicles while offering more flexible gear ratios compared to competitive technologies. The compact 4-speed transmissions also improve system efficiency, enabling longer vehicle range and battery life.

“These transmissions were developed based on existing Eaton ICE technology that we adapted to the EV market,” Hopkins said. “Our goal was to make the shift smooth and quick, but there’s tradeoffs, right? If you make it too quick, it could be jerky. We want to make sure we’re doing the right thing for the application.”

BAE Systems provided the electric motor and power electronics for the test vehicle.

A 4-speed transmission is unique for both commercial and light vehicles but Hopkins stated that because the motor has a larger range of operation, you don’t need as many speeds.

Additionally, the heavy-duty 4-speed EV transmission was named a 2024 Automotive News PACEpilot Innovation to Watch at an awards ceremony in April. This recognition acknowledges post-pilot, pre-commercial innovations in the automotive and future mobility space.

Ride and Drive

The Class 7 demonstration vehicle checked all the boxes for simplifying electric drive systems.

First impressions? It’s uncanny how much room there was under the hood. By emphasizing size and weight reduction and moving the battery pack toward the back of the truck, there’s so much empty space up front. I’ve never seen fewer components in a vehicle or less high voltage orange cables running amok.

The handling and acceleration on the test track were significantly better in the EV vs. the ICE commercial vehicle. It took turns and shifted smoothly, accelerated generously and was an absolute comfort between 60 and 70 mph.

With a hill holding function on the powertrain, I was able to take my foot off the accelerator on steep inclines and the EV truck would hold on to the grade. I imagine this would be an extremely beneficial feature for a delivery driver in heavy traffic in Pittsburgh or San Francisco.

The ICE counterpart performed as expected.

The steering wheel shook harder during acceleration and the overall handling whilst taking curves was nowhere near as comfortable as the EV. Honestly, it felt like driving an old truck as opposed to a shiny, spectacular new EV vehicle fresh off the lot.

As my first drive in an EV commercial vehicle, I was impressed by all the bells and whistles on the inclines as well as the shifting architecture on the test track. Eaton and BAE Systems have delivered on simplifying and reducing the weight of the motor and battery packs. This test vehicle hints at what fleet vehicles could look like moving forward. I thoroughly enjoyed my time behind the wheel.

The empty space under the hood was noteworthy in the EV test vehicle compared to the ICE truck.

What We Learned

It’s one thing to debate about the differences between electrical and ICE vehicles, but I believe if more people had an opportunity to drive an EV and its ICE equivalent back–to–back, you’d see how far the technology has come and what the future actually holds for the transportation industry.

I circle back to discussions at the CTI Symposium earlier this year. Many experts in the automotive, truck, construction and off-highway sectors understand the pushback when it comes to meeting sustainability and CO2 requirements. They realize the infrastructure challenges, the costs, and the market fluctuations. Everyone hears all the noise in politics as well as the media. Regardless, these engineers continue to roll up their sleeves and find the best EV solution for the application.

“Buses—city and school—are doing really well in the EV space,” Webb added. “We hope to see similar results in commercial vehicles and material handling. There are challenges to overcome, but it’s an exciting time to be a part of the electrification movement.”

eaton.com/us/en-us/products/emobility.html

Power Transmission Engineering is THE magazine of mechanical components. PTE is written for engineers and maintenance pros who specify, purchase and use gears, gear drives, bearings, motors, couplings, clutches, lubrication, seals and all other types of mechanical power transmission and motion control components.

Power Transmission Engineering is THE magazine of mechanical components. PTE is written for engineers and maintenance pros who specify, purchase and use gears, gear drives, bearings, motors, couplings, clutches, lubrication, seals and all other types of mechanical power transmission and motion control components.