Ilsemann Automation

SEW-EURODRIVE

Heidenhain

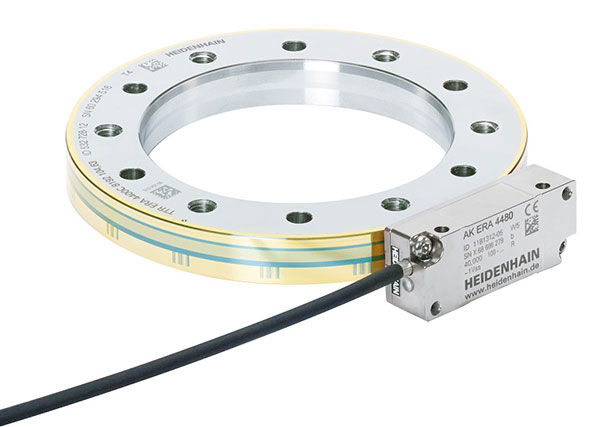

Upgrades Modular Angle Encoder Series

Heidenhain has announced several significant technical upgrades to the already successful ERA 4000 angle encoder series, thereby adding increased reliability and functionality upon a strong foundation. These bearing-less encoders are used heavily in machines in the metrology, machine tool, semiconductor and robotic industries and have been for decades. With these upgrades, the new ERA 4000 series stands alone in accuracy, ease of use and logistical flexibility, and is exactly mechanically compatible with past models.

ERA 4000 angle encoders consist of a steel drum at various diameters with the 20-, 40- or 80-micron graduation on the outer diameter, and a scanning unit that reads the graduation. As an incremental system, there are reference marks available as distance-coded or one per revolution.

The most powerful upgrade to these encoders is adding Heidenhain Signal Processing (HSP) to the scanning units. This feature is an added circuit where the LED is dynamically controlled, and where the scanning unit “learns” of the quality of signal coming back from the drum then adjusts the LED intensity on the very next signal period. HSP operates in an analog way and actually increases the speed capabilities of the encoder system to 1 MHz scanning, a 285% increase.

HSP also powers through contaminations on the drum like fingerprints, dust and liquid droplets, all without amplifying electrical noise as other encoders which are more sensitive to those types of contaminations often do. The result is improved reliability which results in less machine down time.

Two other upgrades to the scanning units are a status LED on the side of the scanning unit which provides unit status helpful during the mounting process, and the addition of a smaller M12 connector which saves space and is more robust.

Heidenhain

Isotech

Offers Slew Rings and Turntable Bearings for Heavy-Duty Applications

The rugged ball-bearing and crossed roller slewing rings from Isotech are characterized by their large diameter and large bores with only a small cross-section. They were designed for axial, radial as well as combined axial and radial loads. New design concepts and improved manufacturing processes for the ball-bearing and crossed roller slewing rings, enable our customer’s designers to implement completely new solution approaches.

Highlights include a bore diameter starting at 50 mm, simple installation, available in various, individual versions, available with internal or external gear and without gear, corrosion-resistant types available on short notice and generally short delivery times.

Applications include agricultural machinery, conveyors, cranes and derricks, excavators, indexed, positional, and rotating tables, industrial robots, lifts, medical scanners and imagers, mining equipment, rotating displays, satellite and radar antennas, solar panels, textile looms, vehicle trailers, and wind and underwater turbines.

Isotech, Inc.

Portescap

PROVIDES DC CORELESS MOTOR FOR HORTICULTURE APPLICATION

Pruning is the most manual and time-consuming job in the Viticulture and Horticulture industries. Light and powerful motorized pruning shears help reduce fatigue and repetitive motion injuries versus manual pruning tools. Motorized pruning shears are able to increase the speed and cutting force while maintaining an acceptable user hand temperature, allowing the operator to complete a full workday.

A European provider of power hand tools needed a customized motion solution on a seasonal timeline for two battery-operated electronic pruning shear applications. The same motor/gearhead composite were able to be used for both applications. The smaller pruning shears were being designed for use in vineyards and smaller orchards. The larger shears were designed for larger parks and gardens.

Portescap was selected as the motion solutions provider based on its expertise in micro-technology, excellent product price-to-performance ratios, and ease of communication. Portescap engineers recommended the 30GT2R82 brush DC coreless motor with the R32 ball bearing mini motor gearhead. This motion solution is able to provide longer battery life thanks to its highly efficient and robust ironless design. In addition, the gearbox and motor commutation are able to withstand high peak torque. The total compact solution was able to allow for lighter hand tools with a longer product life, while also reducing fatigue for the end user.

Portescap

NUM

Launches Digital Twin Technology

CNC specialist NUM has launched digital twin technology that enables machine tool manufacturers to reduce their time to market dramatically, by using powerful Industry 4.0 simulation techniques.

Originally known as pairing technology, and first used by NASA in the early days of space exploration, digital twin technology is now rapidly gaining industry acceptance as one of the most cost-effective means of accelerating the development of products, processes and services.

For automation products such as machine tools, a digital twin is a virtual model that uses simulation, real-time data acquisition/analysis and machine learning techniques to allow full evaluation of a machine’s dynamic performance before constructing a physical prototype. The same technology can also be employed for customer presentations, virtual commissioning, and operator training purposes — and all well before the actual machine itself has even been built.

NUM offers two versions of digital twin technology, to best suit customers’ needs.

Both versions are designed for use with NUM’s powerful, open-architecture Flexium+ CNC platform. One version uses a naked Flexium+ controller and resident virtualization software running on the system’s industrial PC to simulate the twinned machine automation. The other version uses the actual Flexium+ controller that will eventually be incorporated in the machine, linked via EtherCAT to a standalone PC running specialist high speed hardware simulation software to represent the mechatronics of the twinned machine.

The virtual controller version includes a software development kit for creating the software model of the machine. The model is a standalone PLC program that uses predefined components to simulate individual machine elements, such as sensors, spindles, pneumatic cylinders, etc. It is loaded into the integrated PLC of the Flexium+ controller.

The Flexium NCK in the controller executes the NC programs and simulates the changing position values of the machine’s axes. To help users visualize the process, NUM’s package includes the CODESYS Depictor software tool produced by CODESYS GmbH, which is used to produce 3D visualizations from the IEC 61131-3 code created by the simulation.

The other version of NUM’s digital twin technology package accommodates real-time data acquisition and analysis. It is based on the ISG-Virtuos hardware simulation software produced by Industrielle Steuerungstechnik GmbH (ISG). The Flexium+ controller that is intended to be used in the physical machine is connected via an EtherCAT network to a standard PC and interacts with the simulation software in real-time. The PC acts as the twinned virtual machine — with all simulated, virtual components behaving like real components in terms of their interfaces, parameters, and operating modes — to accurately replicate the structure and dynamic performance of the real machine. The movements of the machine are displayed realistically on the PC, using the supplied 3D simulation software.

NUM’s new digital twin technology provides machine tool manufacturers with a very powerful and cost-effective means of reducing their developments costs and accelerating their time to market. The virtual controller version is especially useful for the early development stage of a project, before the CNC system has been finalized, while the real-time hardware simulation version has the advantage that all sequencing (PLC) and motion control (CNC) programs that are created during development can simply be transferred to the real machine as soon as it becomes available.

num

C-B Gear & Machine

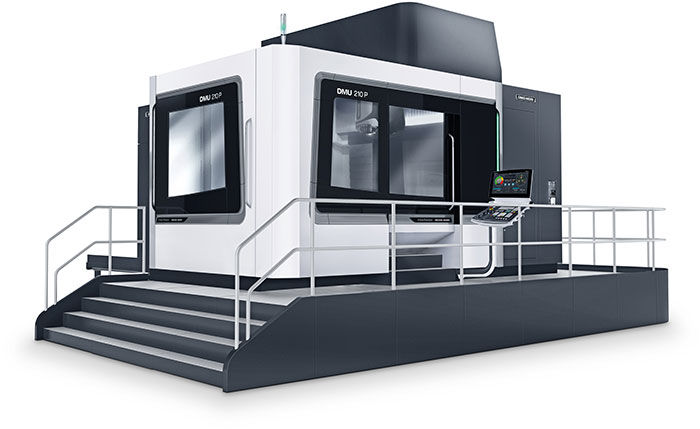

Expands Capability with 5-Axis Milling

C-B Gear & Machine has expanded its precision milling capability with the addition of a new DMG MORI DMU 210P2 5-axis milling center.

The DMU 210P2 is one of a handful of five-axis milling machines in North America that can perform complex milling operations as well as mill gear teeth, making it state of the art machine technology. Reduction in set up and run times give C-B Gear a new capability for the high-speed production of any gear type on the market up to AGMA quality class 12 and higher. Cylindrical and right angle gearing up to 82” in diameter, soft or hard finished are possible.

Additionally, C-B Gear can now produce hard finished spiral bevel gears to either Gleason or Klingelnberg tooth forms. The DMU 210P2 adds to the company’s wide range of large precision gear manufacturing, which complements C-B Gear’s tooth grinding capability up to 4 meters in diameter. C-B Gear is one of the few gear manufacturing facilities in the country with this type of capability in this size range.

“We’re excited about the prospect of expanding into new markets with this type of capability” said C-B Gear General Manager, Frank Irey. “We’ve added all of the bells and whistles that help C-B Gear become even more competitive in the industry with on-board tooth inspection, tool offset compensation and automatic workpiece eccentric adjustments. Customers can expect higher quality and faster turn-around times than in the past”.

Since 1952, third-generation family-owned C-B Gear has been providing a wide variety of industries with quality products at a competitive price. “Expertise in precision mechanical component production, gear manufacturing and aftermarket gearbox repair has established C-B Gear as a highly valued supplier to our customers,” said Irey.

C-B Gear & Machine

Forest City Gear

Expands Threaded Wheel Grinding Capabilities

Forest City Gear now can perform hard fine finishing of larger diameter cylindrical gears faster and more efficiently in higher volumes with the addition of a new Reishauer RZ 410 Threaded Wheel Grinding Machine.

The new Reishauer uses the threaded wheel (continuous generating) grinding process to combine very high metal removal rates and short idle times to produce gears as large as 500 mm in diameter and module 10 and shafts up to 700 mm in length much faster and more efficiently than profile grinding.

For smaller lot sizes, specialized, and prototype work the Reishauer also gives Forest City Gear the ability to perform profile grinding using either CBN plated or dressable grinding wheels that can be modified on the machine with an on-board CNC dressing unit, working in conjunction with integrated inspection.

The unique architecture of the Reishauer also provides optimum speed and accessibility during wheel or workpiece changeover. The turret-mounted grinding spindle can be rotated between grinding position, dressing position and an easily accessible wheel-changing position that allows the operator to change the clamping fixture at the same time the grinding wheel is being dressed on the opposite side of the column.

The capability of this machine to perform threaded wheel grinding, profile grinding, and polish grinding to create gears with ‘mirror’ finishes, along with the ability to control bias, allows it to fit perfectly within Forest City Gear’s very diverse product requirements, according to Forest City Gear Technology Manager Gene Fann.

The capability of this machine to perform threaded wheel grinding, profile grinding, and polish grinding to create gears with ‘mirror’ finishes, along with the ability to control bias, allows it to fit perfectly within Forest City Gear’s very diverse product requirements, according to Forest City Gear Technology Manager Gene Fann.

“The Reishauer adds speed and capacity for production of larger gears at lower cost per piece to our grinding operation, with the versatility to accommodate a very wide variety of customer requirements, whether the high precision of a one-off master gear or ultra-quiet gears with mirror finishes produced in higher volumes,” said Fann. “With quality and delivery standards never higher in all the industries we serve, this machine is a great addition.”

Forest City Gear

Power Transmission Engineering is THE magazine of mechanical components. PTE is written for engineers and maintenance pros who specify, purchase and use gears, gear drives, bearings, motors, couplings, clutches, lubrication, seals and all other types of mechanical power transmission and motion control components.

Power Transmission Engineering is THE magazine of mechanical components. PTE is written for engineers and maintenance pros who specify, purchase and use gears, gear drives, bearings, motors, couplings, clutches, lubrication, seals and all other types of mechanical power transmission and motion control components.