Our Publications

Please select a publication below.

Power Transmission Engineering

April 2024

Volume: 18

Edition: 3

Publisher's Page

Back to TopFeature Articles

Back to TopThe Flexible Factory

See the shift in production lines and technology during Automate 2024

Read More

Master Power Transmission’s Automation Transformation with Ready Robotics

A leadership perspective on advanced automation integration

Read More

Easy Integration

Mayr components offer flexibility and guidance in robotic and automation applications

Read More

Technical Articles

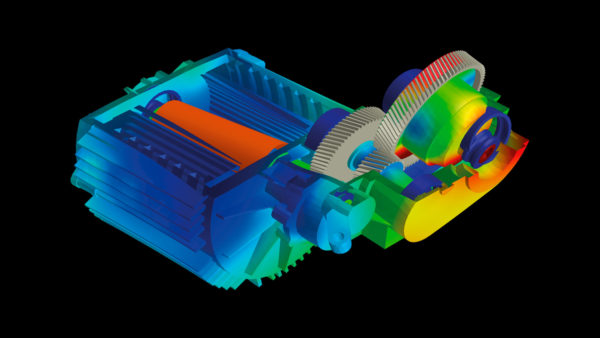

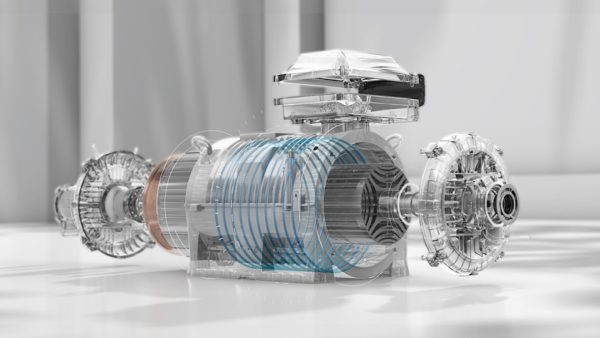

Back to TopFlexibility in Gear Design

Load collectives in the FVA-Workbench expand design capabilities.