Our Publications

Please select a publication below.

Power Transmission Engineering

Publisher's Page

Back to TopFeature Articles

Back to TopHighlights of Turbomachinery & Pump Symposia 2022

A strong post-pandemic turnout brings the turbo and pump industry up to speed

Read More

Bearing Design Considerations for the Food Processing Industry

Materials, closures and lubrication options must be properly selected to ensure the optimal performance of bearings used in this machinery.

Read More

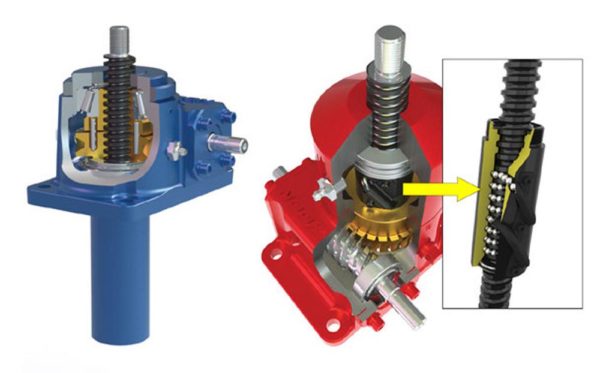

Comparing Machine Screw Jacks and Ball Screw Jacks for Heavy Lifting Capabilities

Engineers should consider the following factors during the design phase

Read More

Technical Articles

Back to TopProduct News

Back to TopABB Expands Smart Sensor to General Machinery

ABB Ability Smart Sensor now available for industrial motors and general machinery including pumps and fans

Read More