Items Tagged with 'Thomson Industries'

ARTICLES

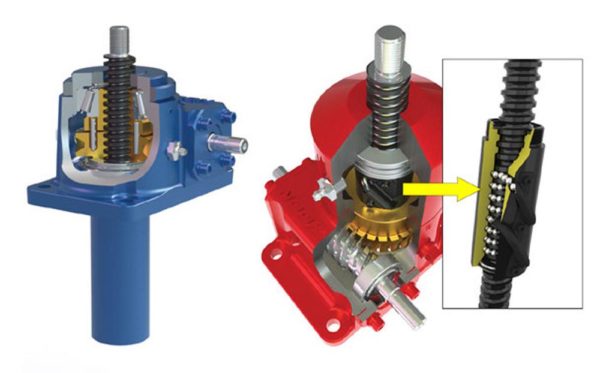

Comparing Machine Screw Jacks and Ball Screw Jacks for Heavy Lifting Capabilities

Engineers should consider the following factors during the design phase

Read More

White Paper

Selecting Linear Bearings for Optimized Round Rail Performance and Cost

Thomson

Read More

When designing for linear motion systems, the initial decision between round and square rail can significantly impact cost, performance and durability. Square rail, which is typically the more expensive option, has a higher load capacity and tighter accuracy. Round rail offers distinct cost and reliability advantages for certain applications, but maximizing those advantages depends on specifying the right bearing to minimize friction in each application. Designers must often choose between plain bearings, often called bushings, and ball bearings. And within each type, they will have more options that impact price, performance, maintainability and durability. Understanding these options early in the design cycle will optimize the performance and cost of the linear motion application.

When designing for linear motion systems, the initial decision between round and square rail can significantly impact cost, performance and durability. Square rail, which is typically the more expensive option, has a higher load capacity and tighter accuracy. Round rail offers distinct cost and reliability advantages for certain applications, but maximizing those advantages depends on specifying the right bearing to minimize friction in each application. Designers must often choose between plain bearings, often called bushings, and ball bearings. And within each type, they will have more options that impact price, performance, maintainability and durability. Understanding these options early in the design cycle will optimize the performance and cost of the linear motion application.