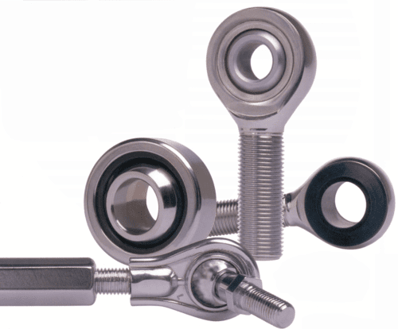

Revolutions

Gerdau Intel Day 2022 Examines Gear/Bearing Steels, Components, and Market Forecasts for the EV Market

Read More

NORD Powers Intralogistics Systems with Modular Drive Solutions

Gear units, motors, and variable frequency drives work in unison to transport items quickly and safely across all intralogistics and warehouse operations

Read More

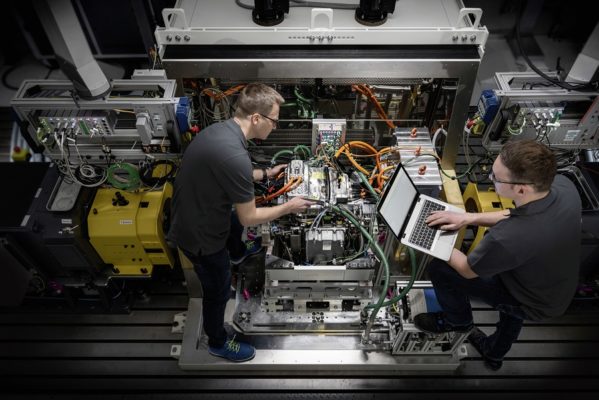

The Electrification Initiative

How Schaeffler is Approaching Electric Motor and Power Electronics Technology Today

Read More

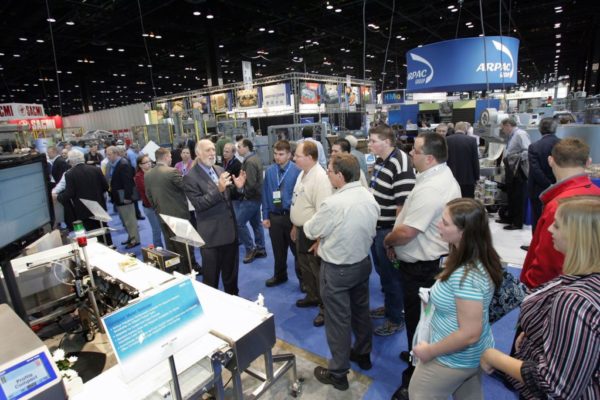

Automation, Robotics and Mechatronics at Pack Expo 2022

Chicago trade show offers innovative packaging and processing solutions

Read More

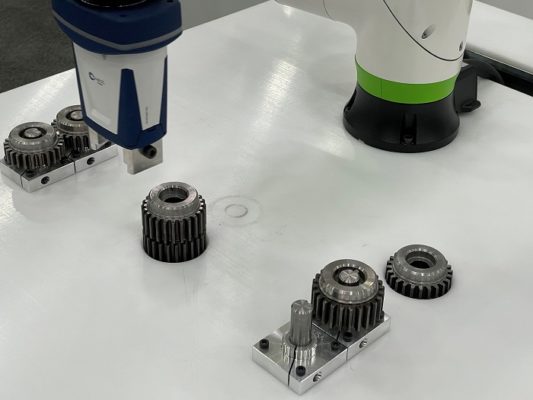

A Guide to Gear Automation

Robotic technologies are designed to handle everything from heavy payloads to miniature components

Read More