When precision and efficiency reign supreme, every component plays a role in ensuring optimal performance. Among these components, gear pumps stand out as essential workhorses, facilitating the smooth transfer of fluid power within intricate systems.

Thus, integrating high-quality, fully configurable gear pumps into power transmission setups is truly transformational when it comes to enhancing performance, reliability, and overall operational efficacy.

Precision Engineering

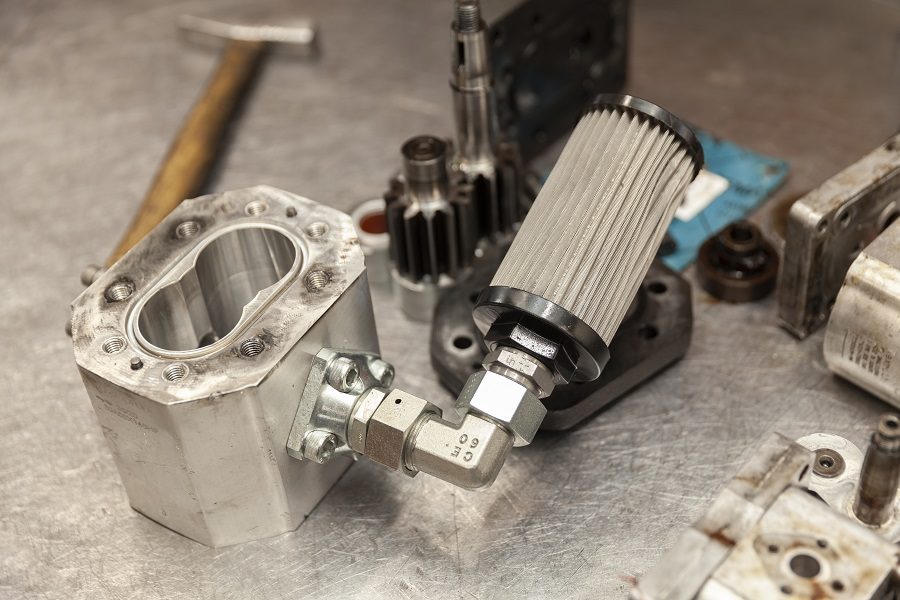

At the initial conception of every high-quality gear pump is precision engineering – a meticulous process that harmonizes design, materials, and manufacturing techniques to achieve unparalleled performance standards. Unlike their conventional counterparts, which often sacrifice precision for cost-effectiveness, premium gear pumps prioritize dimensional accuracy, tight tolerances, and superior craftsmanship.

This commitment to precision engineering translates into a multitude of tangible benefits for power transmission systems. By minimizing internal leakage, reducing fluid bypass, and optimizing flow paths, high-quality gear pumps ensure maximum power transmission efficiency. Every revolution of the pump yields consistent fluid output, fostering smooth and reliable operation across varying load conditions.

On top of this, the inherent precision of these pumps mitigates wear and tear, extending component lifespan and minimizing maintenance requirements. With reduced downtime and enhanced longevity, power transmission systems equipped with top-tier gear pumps enjoy heightened reliability and operational continuity – a critical advantage in industries where uptime is paramount.

The Power of Configurability

In our world, systems must seamlessly accommodate diverse operating conditions, fluctuating loads, and evolving performance demands. Enter fully configurable gear pumps – a feature that empowers engineers with unprecedented control over fluid power management.

Unlike off-the-shelf solutions constrained by predefined specifications, configurable gear pumps offer a blank canvas for customization. Engineers can fine-tune key parameters such as flow rate, pressure rating, inlet/outlet configurations, and mounting options to align with precise system requirements. These pumps can also have priority rear covers installed with flow cartridges that can drive power steering and other systems from one single pump. This configurability not only enhances system performance but also optimizes energy consumption, minimizing waste and maximizing efficiency.

Furthermore, the ability to tailor gear pumps to specific applications unlocks a world of possibilities for innovation and optimization. Whether it's adapting to extreme operating conditions, integrating seamlessly into compact spaces, or interfacing with proprietary control systems, configurable gear pumps pave the way for tailored solutions that elevate power transmission performance.

Sustainability Impact

In an era defined by sustainable engineering practices, the quest for efficiency extends beyond performance metrics to also encompass ecological impact. Herein lies another compelling advantage of high-quality, fully configurable gear pumps – their innate ability to promote energy efficiency and reduce carbon footprint.

By optimizing fluid flow dynamics and minimizing internal losses, premium gear pumps operate at peak efficiency levels, provide extremely low noise levels so when incased in condensed areas they work quietly, and maximize the conversion of mechanical power into hydraulic force. This efficiency not only translates into tangible cost savings for end-users but also reduces overall energy consumption and greenhouse gas emissions. In an industry – and world – grappling with climate change and resource scarcity, every incremental improvement in energy efficiency is significant.

Plus, the configurability of these pumps enables engineers to fine-tune performance parameters for optimal energy utilization across diverse operating scenarios. Whether it's adjusting flow rates for partial load conditions or optimizing pressure settings for peak efficiency, configurable gear pumps empower companies to achieve sustainability goals without compromising performance or reliability.

Operational Cost Reduction

Having high-quality, 100 percent configurable gear pumps can also significantly reduce operational costs in several ways.

Firstly, since these pumps allow engineers to fine-tune parameters such as flow rate and pressure to match specific operational requirements, they optimize efficiency and minimize unnecessary output. Secondly, their durability and longer lifespan compared to lower-quality alternatives result in reduced maintenance, saving companies in labor costs and lost productivity. And these pumps are broken in at the test-stand level, so when the customer receives them, they are contaminate-free.

Additionally, configurable gear pumps can deliver the exact amount of fluid required for a task, minimizing the associated costs of replenishment and disposal. Their improved reliability also leads to fewer unexpected interruptions in operations. And by selecting the right pump for the job and fine-tuning its settings, operators can avoid over-specifying equipment. The modular designs and easy-to-service components of these pumps simplify maintenance tasks, reducing the time and labor required for routine upkeep.

And of course, their efficient operation results in energy savings, contributing to lower overhead costs. Overall, investing in high-quality, configurable gear pumps offers significant cost-saving opportunities across the pump's lifecycle, making these configurable pumps a valuable asset for businesses seeking to reduce expenses.

Hydraulic Innovation

Leading proponents of hydraulic technology, such as Bailey International, are spearheading advancements in gear pump configurability.

Through an extensive range of gear pumps, Bailey offers flexibility in tailoring fluid power solutions to meet the unique needs of diverse applications. Detailed configurability, including tandem and stacking in many configurations up to six sections, ensures that Bailey's gear pumps can be precisely adapted to the most complex requirements. With a focus on precision engineering and sustainable performance, Bailey's gear pumps embody the principles of reliability, efficiency, and adaptability – qualities that resonate deeply with the ethos of power transmission engineering.

As organizations strive to optimize performance, reduce environmental impact, and drive innovation, companies like Bailey International stand as trusted partners in the journey to hydraulic excellence. With configurable gear pumps that empower engineers to unlock new levels of efficiency and precision, suppliers are reaffirming their commitment to shaping the future of power transmission engineering – one customized solution at a time.