Introduction

In paper mills throughout the country, gearboxes provide an integral solution for power transmission. Each is selected particularly and directly to perform a specific task in the production of paper. Due to the critical nature of the equipment, all gearboxes are heavily monitored and periodically inspected for preventive maintenance. If necessary, gearboxes can be reconditioned by replacing or repairing components with the intent to rebuild the entire gearbox to OEM specifications.

Paper and pulp mill.

Paper and pulp mill.

In a paper mill, one of the gearboxes used on the paper machine floor is a Beloit differential drive. These gearboxes provide four basic functions:

•Precise, positive sheet tension control from section to section by mechanically tying the sections in the whole paper machine together while at the same time allowing each section speed to be controlled independently.

•On-the-go-speed changes for each section to be precise, stepless and infinitely variable within a given range.

•Accurate monitoring of the horsepower demand of each section.

•A right-angle drive from the line shaft to power the paper machine.

These functions are critical in the production of paper. Generally, if well maintained, Beloit differentials can operate properly for many years. However, when one fails, it is critical to rebuild it to OEM specifications for proper operation.

Differential Shaft Assembly Illustration. (Beloit Technical Manual)

Differential Shaft Assembly Illustration. (Beloit Technical Manual)The Beloit differential consists of seven shaft assemblies. Power is inputted into the gearbox through the line shaft assembly. The line shaft gear drives the outer gear on the differential shaft assembly at a constant speed proportional to the line shaft speed, which is generally 1,000 rpm. The first outer gear, which is a Zerol bevel gear, drives one side of the Zerol bevel spider gears on the differential shaft, as well as the PIV input shaft. The PIV, through a variable speed arrangement, changes the ratios as required and drives the PIV output shaft. The PIV output shaft gear drives the differential second outer gear through the primary and main variable shafts. The second outer gear, which is a combination spur-Zerol bevel gear, drives the outer side of the Zerol bevel spider gears on the differential shaft. The spider gears cause the differential shaft to average the input speeds of the first and second outer gears of the differential. The differential shaft drives the bevel output shaft, which transfers power to the transfer case gearbox.

Atlanta Gear Works, located in Dawsonville, Georgia, specializes in rebuilding power transmission equipment. Since 1988, the company has been rebuilding Beloit differential gearboxes with a commitment to repair or rebuild every differential equal or better than OEM specifications. Since a failed differential can have a multitude of wear-damaged components, Atlanta Gear Works follows a time-proven process that starts with a thorough analysis of all components.

Disassembly and Inspection

When we receive a damaged differential at our repair facility in Dawsonville, the first thing we do is issue it a quote number and oversee an engineer to oversee the rebuild. Before disassembling the gearbox, we perform a complete inspection documented by photos of each step in the inspection. During this step, we measure each shaft assembly’s end float and runout, as well as roll a pattern and measuring backlash for each gear mesh. We use these measurements as indicators in the root cause failure analysis.

After the inspection and documentation, we then completely disassemble the gearbox, removing all components from each assembly. As a Platinum Timken Certified Service Center, we then submit each component potentially suitable for reuse to a 12-point bearing measurement inspection to verify the condition of the bearing mounting surfaces per the Timken Specification. We perform in-house NTD inspection on all gearing being reused to assure there are no cracks and the gears are suitable for reuse. Additionally, we can "kiss grind" the gears to improve quality.

At the completion of disassembly, the engineer assigned to the gearbox reviews the condition of all gearbox components with the disassembly technician. The engineer then uses the data to generate a reconditioning report. This report illustrates the root cause of failure for the gearbox as well as the condition of all internal components. This report provides our customer a complete picture of their gearbox’s present condition and what is necessary for the gearbox to be rebuilt to OEM specifications.

Gearbox Rebuild

Upon customer approval, we begin the gearbox rebuild procedure. The Engineering Department generates and distributes all required component drawings and production routings. To ensure OEM quality, we machine all gear clusters in-house based on Beloit OEM gear cluster set-up fixtures we purchased years ago. After all components have passed QC measurements, we gather them for assembly.

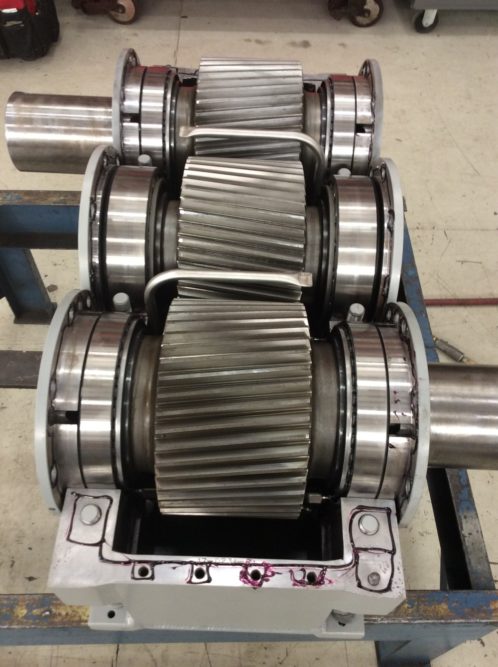

All gears and shafts are reassembled in complete working order. Each shaft assembly is dynamically balanced to the required specification given the application. This assures there are no issues regarding unbalanced components in the gearbox assembly. All bearings are then assembled to the shaft assemblies, with assemblies then placed into the gearbox housing.

With assembly of the differential complete, we perform a no-load spin test at the design input speed of 1,000 rpm. We run the test for a minimum of two hours, during which we measure bearing temperatures, shaft assemblies’ vibration and the gearbox’s overall noise level. If the differential testing temperature, vibration, and auditory values are verified to be of an acceptable value, we move to the final step in the rebuild.

The final steps include installing any couplings the customers requested, final painting of the differential with a two-part epoxy paint and rust prevention. The result is a like-new Beloit differential gearbox that we will prepare for shipment back to the customer.