ctrlX Automation Cube

This unique, four-sided demo illustrates the modularity and scalability of ctrlX AUTOMATION while presenting an overview of ctrlX DRIVE and ctrlX CORE hardware capabilities. On display is a three-axis ctrlX DRIVE linked to a ctrlX CORE industrial PC running in real-time. Other components, such as ctrlX IO, ctrlX HMI and the MS2N synchronous motor, are also included. In addition, the exhibit demonstrates how ctrlX CORE supports modern languages for today’s industrial machinery, such as Java, Python and Node Red, plus many other application-appropriate languages.

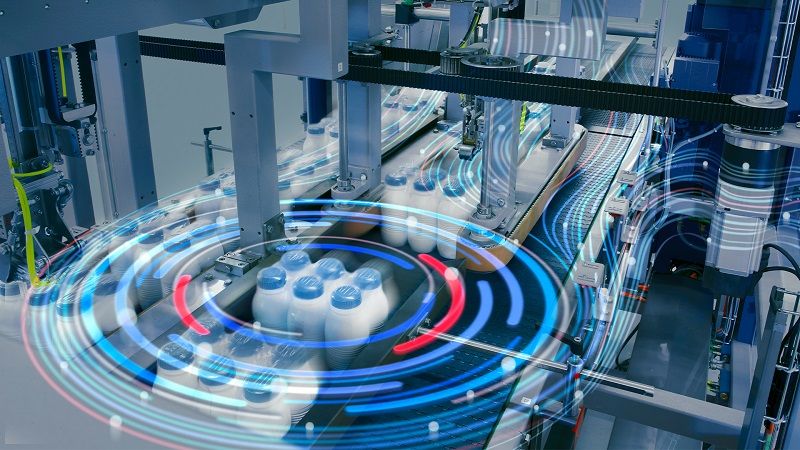

VarioFlow Plus Plastic Chain Conveyor

This unique, four-sided demo illustrates the modularity and scalability of ctrlX AUTOMATION while presenting an overview of ctrlX DRIVE and ctrlX CORE hardware capabilities. On display is a three-axis ctrlX DRIVE linked to a ctrlX CORE industrial PC running in real-time. Other components, such as ctrlX IO, ctrlX HMI and the MS2N synchronous motor, are also included. In addition, the exhibit demonstrates how ctrlX CORE supports modern languages for today’s industrial machinery, such as Java, Python and Node Red, plus many other application-appropriate languages.

AMR

The MP1000R is a 1000kg capacity autonomous mobile robot (AMR) that uses Laser SLAM-based technology developed by Bosch Rexroth to develop a "map" of the work environment and move without human intervention to deliver materials safely and reliably across a warehouse or factory.

Unlike automated guided vehicles (AGVs) that require predefined routes, markers, guides, and human intervention to make changes, the MP1000R navigates autonomously without additional infrastructure. With Rexroth’s Locator mapping software, the AMR will continue to update the map and improve it over time as the facility environment changes.

Smart Handling Kit

Bosch Rexroth’s Smart Function Kit for Handling is an innovative preassembled multi-axis robot made up of tailored, standardized modules and components, which can be put together quickly to form smart subsystems. Simply select and adapt the basic type online, configure and order it, and commission it with software guidance.

boschrexroth.com

KUKA Robotics—#N-6236 (North Building)

At Pack Expo 2022, KUKA Robotics will feature several productivity enhancing automation solutions designed specifically for the Fast-Moving Consumer Goods industry sector. In Booth #N-6236, the company will spotlight its range of fully hygienic robots for food processing, picking, packaging, palletizing and advanced vision applications.

With the utmost cleanliness and safety in mind, KUKA has expanded its robotic portfolio with the addition of Hygienic Machines (HM) and Hygienic Oil (HO) robots. This wide array of products allows today’s food processing companies to apply robots to tasks considered difficult, if not impossible, to automate.

KUKA’s HM portfolio includes robots such as the AGILUS HM and others, all of which feature corrosion resistant surfaces like stainless steel flanges and other key components. Robot arms use food-compatible lubricants in all axes and have smooth surfaces for easy cleaning, this is where KUKA’s HO portfolio comes into play.

For fully automated palletizing/depalletizing, KUKA will demonstrate its KR IONTEC medium payload robot mated with a robotic pick-and-place solution. The KR IONTEC, a highly flexible robot with the best work envelope in its class, will be integrated with 3D-vision to detect stationary items with rectangular surfaces and determine their position, orientation and size for picking. Once the box locations are identified, the KR IONTEC, which is suitable for a vast array of industrial applications including handling, packing and palletizing, will complete the next pick action for fast, efficient stacking.

Designed to simulate a real production environment and automation solutions for each step – moving material from receiving and sorting to packing and distribution – the KUKA end-to-end automation cell will include the company’s KR 3 DELTA Hygienic robot, KR 6 SCARA and KR 6 AGILUS robots and KUKA.VisionTech advanced vision software. The KR 3 DELTA hygienic robot provides outstanding performance and value for pick-and-place applications for the food, packaging, electronics and pharmaceutical industries, while the KR 6 SCARA is strong, fast, highly efficient and delivers maximum economy. KUKA will pair both robots with its KUKA.VisionTech.

KUKA’s six-axis KR 6 AGILUS adapts to any installation position and is designed for particularly high working speeds, boasts a 10-kg payload and comes in a wide range of variants for challenging applications such as clean rooms and potentially explosive environments. KUKA’S KMR iiwa that combines the sensitive KUKA LBR iiwa lightweight cobot with a mobile, flexible platform will work with the three cell-based robots and complete the fully automated end-to-end solution.

As with all the company’s automation solutions, those that will be shown at Pack Expo are backed by KUKA’s expert service and support for training, complete system engineering and simulation, readily available spare parts, robot refurbishment and more. All of which are easily accessible through the my.KUKA.com site, and KUKA maintains corporate offices and production operations, along with integration partner facilities, conveniently located throughout North America to provide responsive customer service and support.

kuka.com

Emerson—#N-4736 (North Building)

Emerson’s tools, technology and expertise can help packaging and production lines reduce waste, empower decision making, improve facility safety, sharpen the accuracy of critical measurements, increase machine availability and much more.

Innovation Stage session:

In addition to its advanced solutions, Emerson will also present "Reduce Waste & Increase Efficiency in Clean-in-Place (CIP) Process." During the workshop, Emerson’s manager of business development, Vince Massey, will share seven common CIP efficiency challenges and the most effective ways to solve them using proper measurement instrumentation. Pack Expo attendees can join the 12 pm session on October 25 at Innovation Stage 1 (N-4560).

Product highlights:

The GSX-E1 Series: Elite Precision is the first of a new generation of ultrasonic welders based on the Branson GSX Ultrasonic Welding Platform, which supports the growing demand for energy-efficient assembly of a variety of more challenging materials, including bioplastics and nonwovens. This modular, flexible joining solution provides greater precision and control, ensuring weld quality and improved operational efficiency. An advanced actuation system reduces trigger force and improves position accuracy, leading to faster, high-performance welding. This is complemented by hardware and software features that simplify setup, operation, and maintenance, while digital connectivity supports Industry 4.0/IIoT applications that provide CPGs access to actionable performance and diagnostic data.

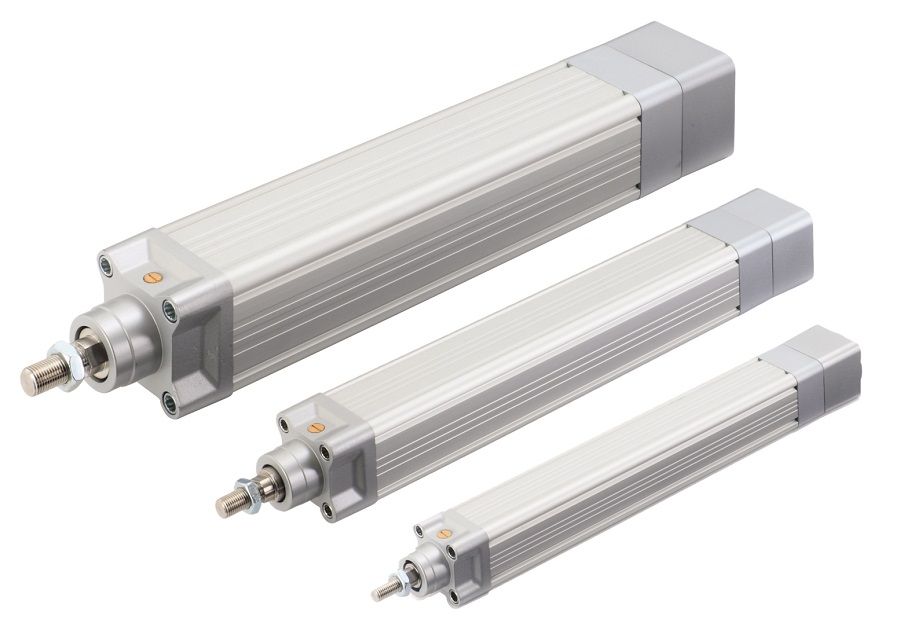

From conveying to assembly, many applications in today’s packaging lines can benefit from the energy efficiency and power of electrical linear motion. Emerson’s Aventics Series SPRA electric rod-style linear actuator is a cost-effective, high-performance solution, offering enhanced load capacity, accuracy and reliability CPGs need to maximize productivity. In addition to providing outstanding precision and repeatability, the Series SPRA is also extremely versatile and flexible, with a choice of three different screw technologies that allow implementation within a wide range of applications and can meet exacting application requirements. Compliance with the ISO-15552 standard, online selection tools and a wide range of mounting accessories ensures the appropriate implementation.

It’s estimated that food and beverage plants spend 30 percent of utility resources on clean-in-place operations and lose valuable time during changeovers — but they don’t have to. Emerson’s new CIP Utilities and Automated Reporting Analytics package delivers utilities monitoring and automated reporting for clean-in-place (CIP) and steam-in-place (SIP) applications. Designed for the food and beverage industries, the package can be delivered via PACEdge or Movicon.

Smart pneumatic sensors are highly effective sustainability tools that can help CPGs reliably save energy, reduce costs, and meet ambitious targets. Emerson’s Aventics Series AF2 airflow sensor has successfully improved the energy efficiency of packaging equipment in a variety of applications, including food and beverage, personal care and even labels. Emerson now offers a high flow model of this advanced sensor that propels compressed air monitoring beyond individual machines to benefit larger air lines and systems. This expanded capability allows personnel to easily optimize energy consumption across an entire packaging facility and improve overall plant sustainability.

Movicon.NExT HMI/SCADA is a highly modular, highly scalable platform that goes beyond SCADA to solve automation problems for both CPGs and original equipment manufacturers (OEMs), from the single machine level to a complete plantwide industrial internet of things (IIoT) project implementation. Among Movicon.NExT modules, Movicon Pro.Lean provides performance data and analytics for evaluations of OEE and Movicon Pro.Energy measures and tracks consumption, while the advanced Movicon NExT.AR solves operational problems through visualization tools that allow personnel to evaluate previously unreachable equipment. For maximum flexibility, Emerson also provides Movicon WebHMI, an HTML5-based visualization tool that can be used as a stand-alone HMI product running on Windows or Linux operator panels, or as a Web Client for Movicon.NExT SCADA applications, as well as Connext, an industrial protocol gateway.

Industrial edge software and solutions help members of the packaging and food, and beverage process industries analyze and solve problems where they occur — at the machine edge. PACSystems Edge Solutions include the true edge controllers, edge computing devices and compact controllers and leverage Movicon.NExT, WebHMI, Connext OPC UA server and the PACEdge platforms in optimized software packages to provide powerful and flexible connectivity and visualization and a cloud-enabled toolset. PACSystems makes the move to the edge easy for members of the packaging and process industries.

emerson.com

For additional coverage of Pack Expo visit:

powertransmission.com/articles/8860-keep-up-with-change-at-pack-expo-international-2022

packexpointernational.com