Applications for gearmotors are extremely varied as are the design and optimization tools available today. From online software to performance standards, here's the latest news on gearmotor technology.

Bison Gear Examines Gearmotor Quality

Product quality is a critically important consideration when purchasing electro-mechanical components, such as electric gearmotors. But what does quality mean and how do you evaluate it as a customer?

Obviously, quality involves materials and manufacturing processes that consistently result in high-performing, defect-free products that conform to specifications. That’s necessary, but not sufficient in ensuring that the product performs as needed in the particular application under the particular conditions for the intended lifespan. Learn how to go beyond the basics to ensure quality in this blog from Lindsey Padilla, director of quality, Bison Gear and Engineering:

bisongear.com/torque-talk/post/going-beyond-the-basics-to-ensure-quality

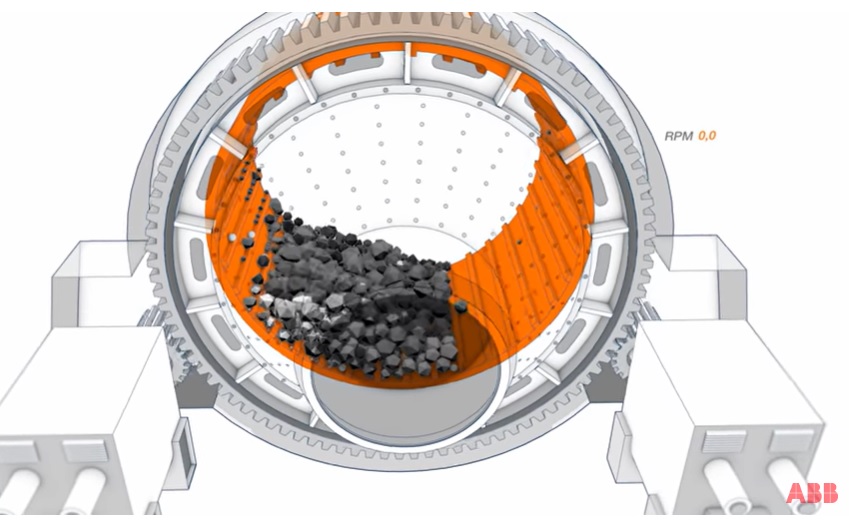

Where are the Gearmotors?

The possible applications for gearmotors are exceptionally varied. Without gearmotors, the entire global economy would come to a standstill. In industrial production, they drive a countless number of conveyor lines, lift and lower loads, and move the widest variety of different goods from A to B in all types of systems.

In the automotive industry you can find gearmotors throughout the manufacturing process, from the press shop to final assembly. Likewise in the beverage industry where they move bottles, packaging units, and crates of drinks and are used when filling containers or sorting empty goods. Every intralogistics company relies on drives, whether they have to store, sort or supply goods.

The same with airports, where nothing would work without gearmotors, and passengers would spend futile hours waiting for their bags at baggage claim.

Handling machines and robots, which require a high level of dynamism and accuracy, would be unthinkable without servo gearmotors.

Last but not least, there would be no such thing as fairground rides in the entertainment industry and the feeling of butterflies in your stomach on the roller coaster would probably be unheard of.

seweurodrive.com/products/gearmotors/gearmotors.html#standardgetriebemotoren

JIE Offers 3D CAD Configurator

JIE USA has released a 3D CAD gearbox and gearmotor configurator to help engineers choose motors and drives on-demand. The online tool enables engineers to identify the correct product for their design or application based on custom parameters and deliver the CAD model or PDF datasheet they need to do their job efficiently.

“Previously, customers would send us all their application information, and our engineers selected the right product for them. This meant a lot of back-and-forth with the customer if we had any questions, which took a lot of time,” said Bo Chen, president of JIE USA Inc. “Now customers can self-serve online. They enter the parameters of their application, like input power, ratio, torque, and output RPM, and the configurator recommends a compatible gearbox or gearmotor. It’s more efficient and lets the customer work on their own time rather than contacting us directly.”

JIE has also introduced configurable 3D PDF datasheets that include essential product data that their customers need.

“With these PDFs, customers don’t have to come back to us for missing data points for the product,” Chen said. “The PDF shows everything related to the product.”

“We’re really excited about this configurator. It lets customers build a compatible system on their own, and it shows everything they need to know right on the page. It’s putting design power in the customer’s hands,” he added.

powertransmission.com/articles/8626-jie-usa-inc-introduces-3d-cad-configurator