High-Performance Upgrades

Linear Motion Demand Increases in Key Market Segments

Product design remains the most fascinating aspect of linear motion components as manufacturers try to answer the speed, size and efficiency challenges of customers utilizing rails, tables, actuators, sliders and other components. Companies like Heidenhain, AMTEK, NB Corporation and PBC Linear continue to provide technologies that increase productivity in this rapidly evolving market segment. Credit e-mobility, robotics, semiconductor and automation technologies for the market growth.

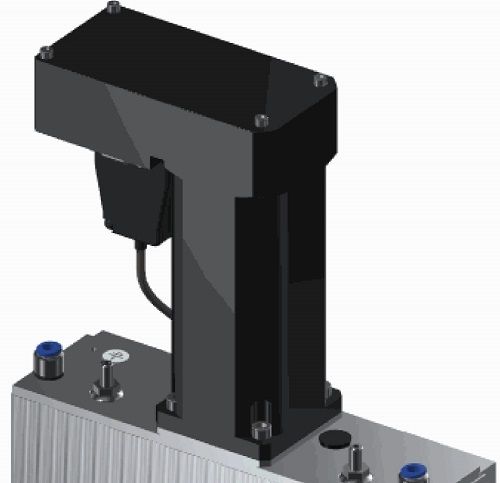

AMETEK Linear Actuator Delivers Precise Movements in Small Package

AMETEK Haydon Kerk Pittman recently released its 15000 Series stepper motor linear actuator—known as the LC15/LE15—with an encoder option. These actuators are available in captive and linear versions, with a variety of resolutions ranging from 0.02 to 0.10 mm per step. The 15000 Series can-stack stepper motor linear actuators deliver force of up to 8 pounds (35N) without compromising longevity or cost. In addition, models can be micro-stepped for finer resolution. The new encoder option offers closed-loop control, an added benefit to the actuator’s small size. Applications for the LC15/LE15 actuators with encoders include medical automation and other automated devices requiring precise, remote-controlled linear movements in a very small package.

NB Corp. EXRAIL Linear Guide Offers High Performance Characteristics