Articles by Matthew Jaster

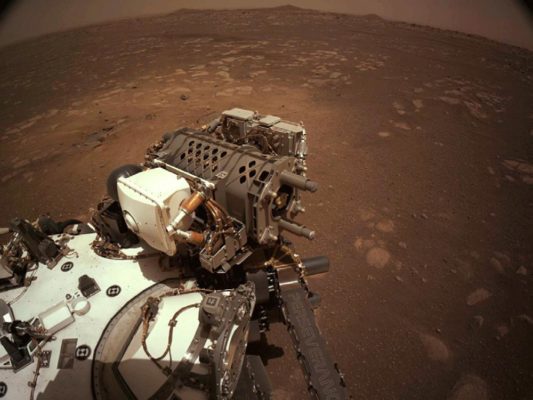

Perseverance traverses Mars to answer questions about the future of space exploration

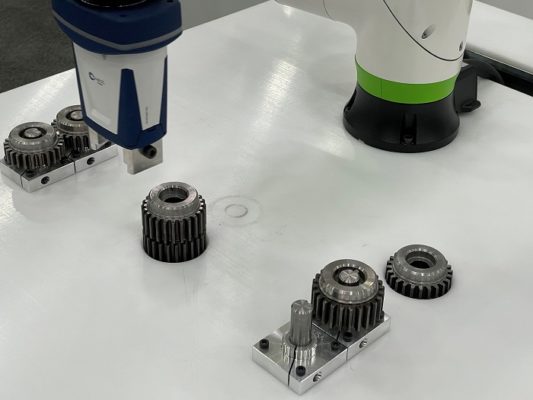

A Guide to Gear Automation

Robotic technologies are designed to handle everything from heavy payloads to miniature components

Read More

An Automotive and Industrial Difference Maker

The Unique Story of Schaeffler’s Needle Roller Bearing Design

Your Robotic Coworker

FANUC Examines the Role of Collaborative Robots on the Automated Shopfloor

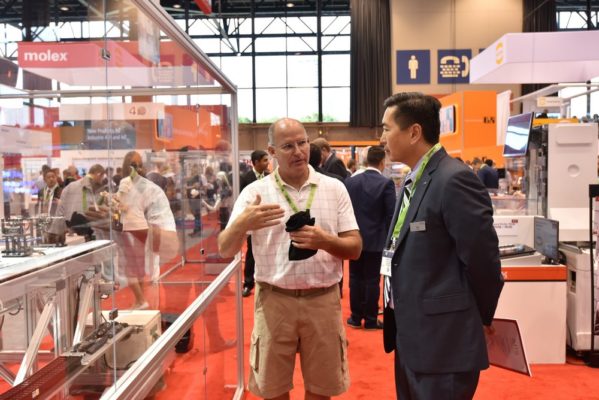

Hannover Messe USA: It's Educational

Attendees will find a comprehensive conference and technology focus at IMTS 2022

Always Fit to Print

What would a trade magazine be without a healthy low-ratio, high-speed gearing system?

Read More

The Optimization of 70 Tons of Scrap

Electric pre-shredder provides energy efficient option with MAV shrink discs

Read More