Aaron Fagan

Aaron Fagan is Senior Editor with Gear Technology magazine and Power Transmission Engineering.

ARTICLES

The shipping sector’s regulatory requirements stipulate all ships must manage their pollution

Read More

Get Pumped for TPS 2023!

An essential annual industry event for rotating equipment engineers and technicians worldwide

Read More

Brakes and Clutches for Integration into OEM Applications

Flexible solutions from Force Control, Miki Pulley, and Ringfeder

June 5, 2023

Metaphor: An Object in Motion

Streaming now on Netflix is director Noah Baumbach’s adaptation of author Don DeLillo’s 1985 classic White Noise, a postmodern campus novel about the dangerous influence of the careless use of scientific inventions and technology which won the National Book Award the year it was published.

March 21, 2023

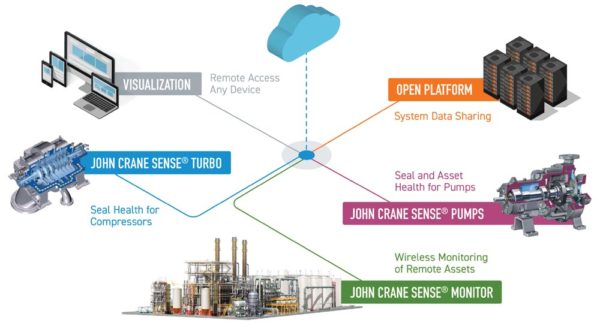

Peering into the Crystal Ball on Condition Monitoring Technology

The future of smart components for motion control systems looks bright

March 21, 2023

Wind of Change

The “electrify everything” movement continues to drive innovation

December 2, 2022

Highlights of Turbomachinery & Pump Symposia 2022

A strong post-pandemic turnout brings the turbo and pump industry up to speed

December 2, 2022

Free Power Transmission Engineering Subscriptions

Free Power Transmission Engineering Subscriptions

FEATURED VIDEO

August 9, 2024

RECOMMENDED

-

Operational Improvements

December 11, 2024 -

Power Density Progress

December 2, 2024 -

CCTY Tackles Humanoid and Industrial Robot Development

September 13, 2024

-

The Future of Power Manufacturing, Warehousing, and Logistics

October 28, 2024 -

5 Ways to Save Money Through Ultrasonic Analysis

December 11, 2024

-

The Future of Power Manufacturing, Warehousing, and Logistics

October 28, 2024 -

5 Ways to Save Money Through Ultrasonic Analysis

December 11, 2024 -

Operational Improvements

December 11, 2024