Software

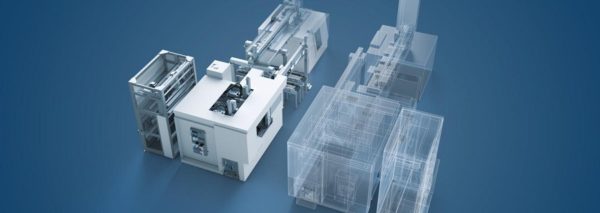

Mechatronic Methodology

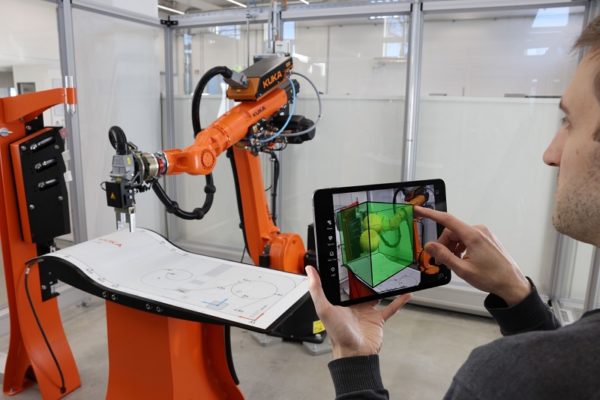

Iljin Electric Collaborates with Siemens Digital Industries on Product Development

Read More

2024 Trends in Fluid Power

AI, smart manufacturing, electric vehicles, and product specification highlights industrial shift

Read More