Maintenance

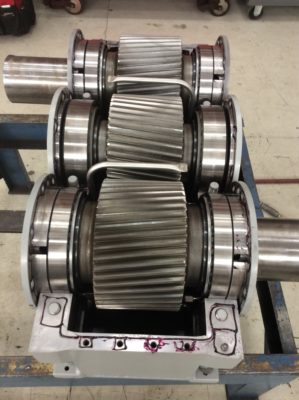

Paper Mill Precision

Atlanta Gear Works Offers Step-by-Step Process for Rebuilding a Beloit Differential

Read More

Advancing Technology for MRO

Sensors, drones, and software highlight latest condition monitoring tools for PT components.

Read More

Desktop Belt Drive Services with Gates

Software platform provides end-to-end mobile troubleshooting and file management capabilities.

Read More