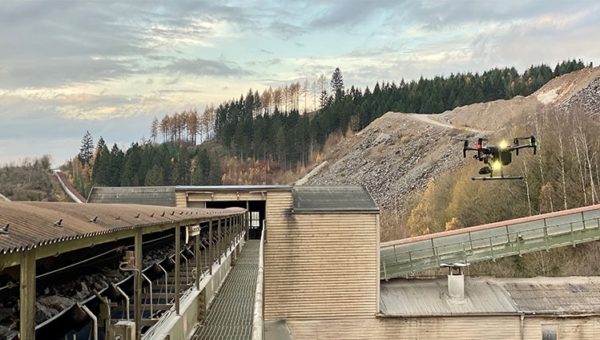

Condition Monitoring

The New Year’s Ball Drop wouldn’t be possible without a sophisticated electromechanical system that must operate reliably during the most critical 60 seconds of the year.

Read More

Metaphor: An Object in Motion

Streaming now on Netflix is director Noah Baumbach’s adaptation of author Don DeLillo’s 1985 classic White Noise, a postmodern campus novel about the dangerous influence of the careless use of scientific inventions and technology which won the National Book Award the year it was published.

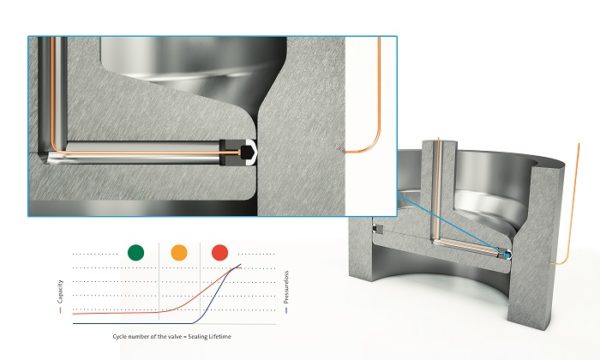

Peering into the Crystal Ball on Condition Monitoring Technology

The future of smart components for motion control systems looks bright

Read More

First Impressions

IFPE and CONExpo/CONAGG Support Thriving Construction and Off-Highway Markets

Read More

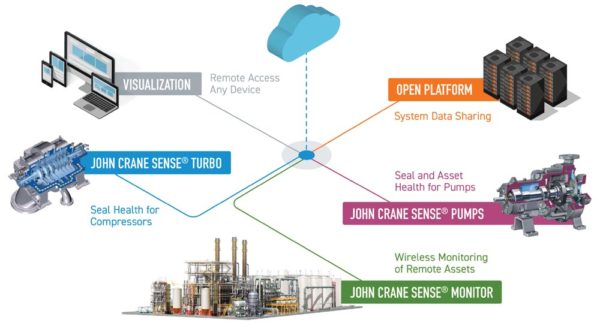

Asset Management in Manufacturing

Accessibility, transparency and digital transformation push condition monitoring technology toward a collaborative future

Read More