IIoT

Digital Transformation Drives the Future of Packaging

Expanding use of new and emerging technologies offers major opportunities to improve sustainability, efficiency, and production

Read More

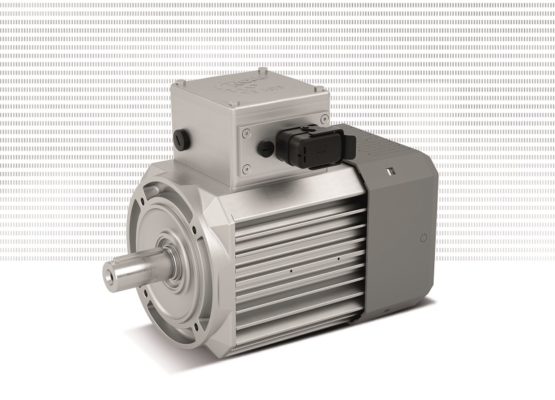

Advancing Technology for MRO

Sensors, drones, and software highlight latest condition monitoring tools for PT components.

Read More

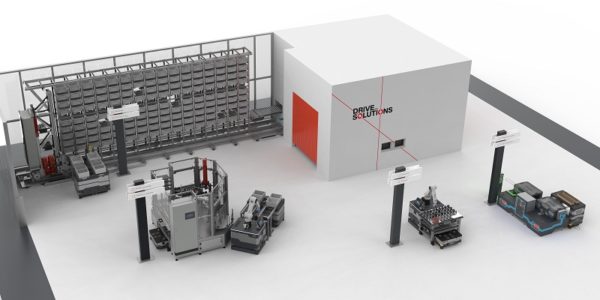

The Candy Man Can

How AI improves automation and motion control with reinforcement learning

Read More