Noise

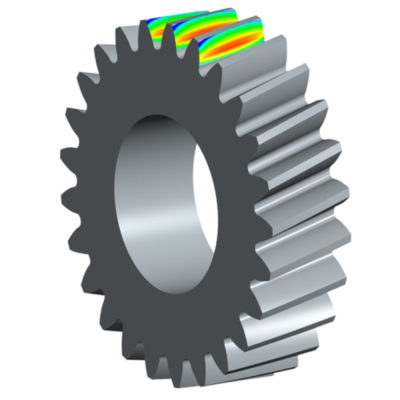

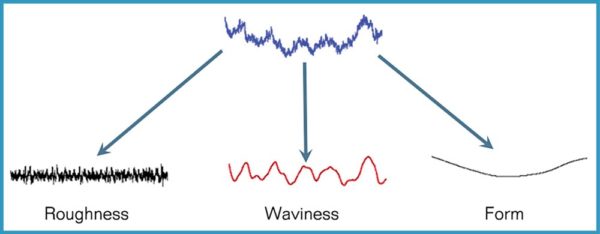

Surface Roughness Is More than a Number

Powertrain components are affected by vibration, noise, wear, thermal characteristics and more

Read More

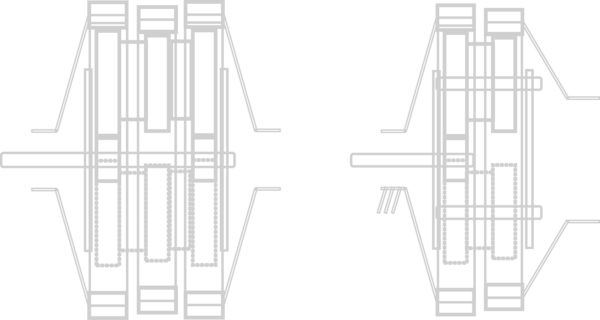

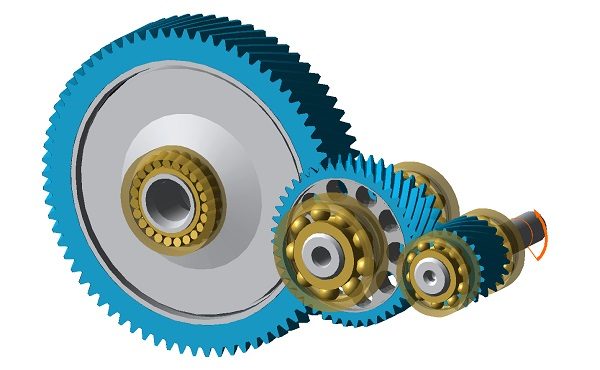

KISSsoft Supports Student Racing Team in Taiwan

Mechanical engineering theory, design and practice come into play for NYCU Vulpes Racing Team

Read More