Bearing Lubrication

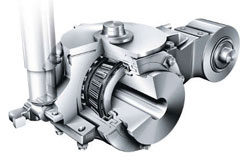

PTE Bearing Basics and Innovations

Power Transmission Engineering Highlights Latest Bearing Technology

Read More

Bearing Basics and Beyond

Power Transmission Engineering (PTE) Has Your Bearing Education, Training, and New Developments Covered Every Issue

Read More