Technical Articles

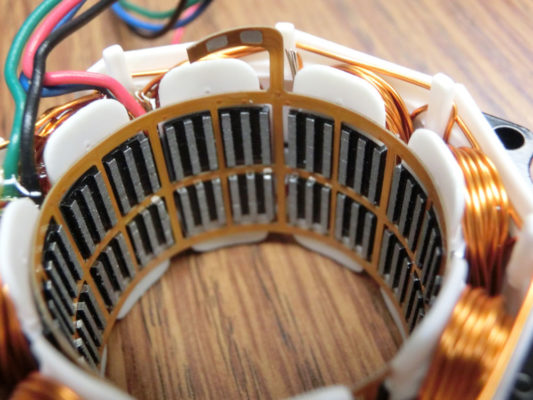

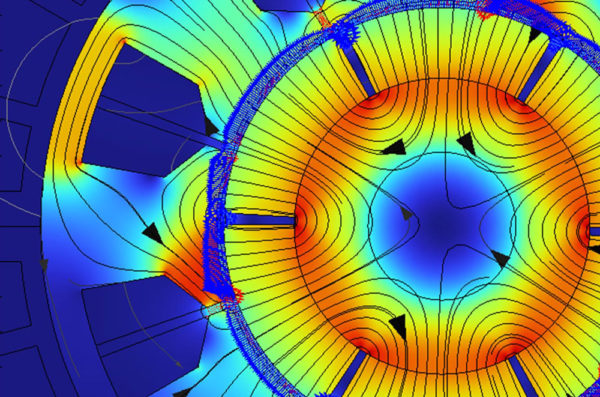

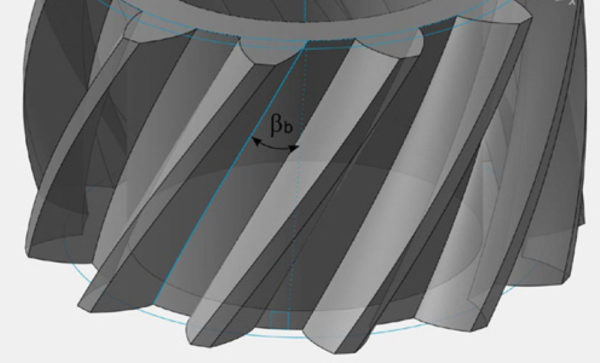

Noises in the Night

The factors leading to ultra-quiet electric motors

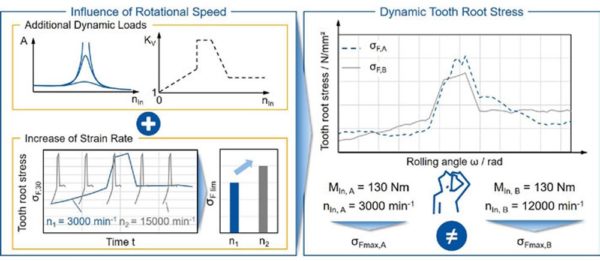

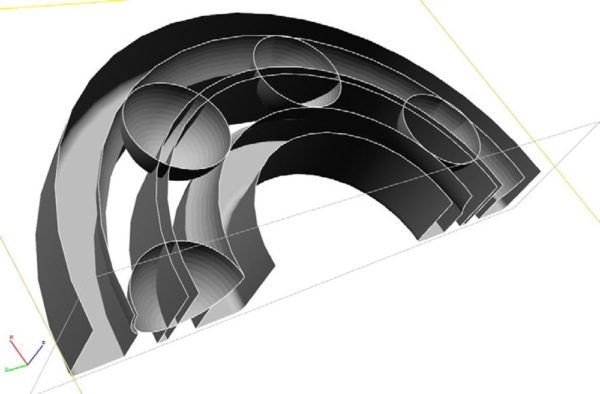

Reliable, User-Friendly Planetary Gear Unit Design

Stober Relies on FVA Workbench for Drive Verification

Read More

Using and Specifying Flexible Couplings

Prepared by members of the AGMA Flexible Coupling Committee

Read More