Feature Articles

2024 Trends in Fluid Power

AI, smart manufacturing, electric vehicles, and product specification highlights industrial shift

Read More

Advancing Motion and Power: A Conversation with Roger Thomas from Flender Corporation

From the “Ask the Expert” stage at Motion + Power Technology Expo 2023

Read More

Building a Better Bearing

An innovative look at analysis, condition monitoring, mounting and maintenance.

Read More

Vesconite Bearings Invests in Energy Efficiency in South Africa

Factory reduces reliance on power grid to enhance 24/7 operation

Read More

Solid Edge 2024 Focuses on Performance and User Experience

A Q&A on the latest software update

Read More

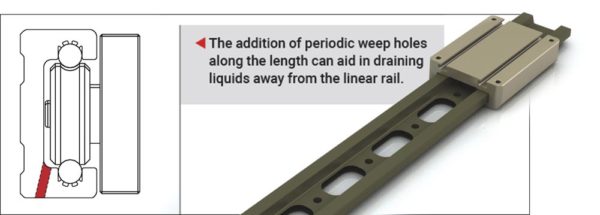

Design Tips for Linear Motion Systems in Washdown Applications

Designing linear motion systems for washdown applications requires careful component selection to solve problems associated with contamination as well as liquid and chemical interactions.

Read More

Bearing Design Considerations for Pumps and Compressors

Loads, life, fits, material, and lubrication must all be evaluated to ensure optimal performance of turbomachinery.

Read More