Planetary

Having a Ball: The Technology Behind the Ball Drop

The New Year’s Ball Drop wouldn’t be possible without a sophisticated electromechanical system that must operate reliably during the most critical 60 seconds of the year.

Read More

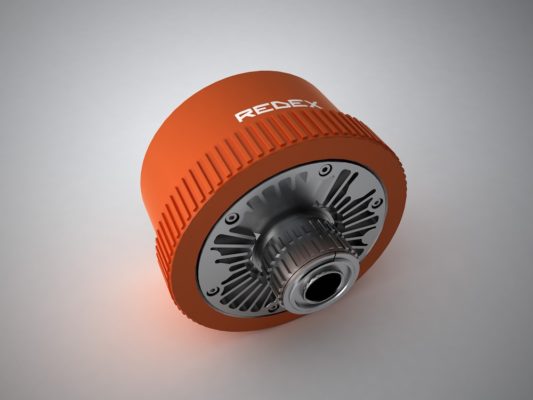

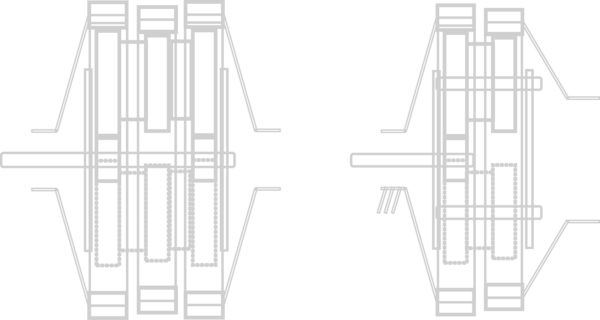

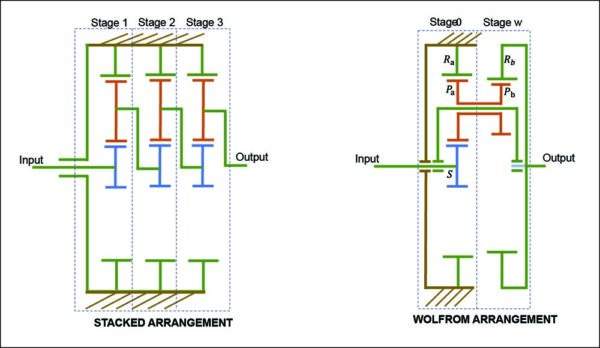

Reliable, User-Friendly Planetary Gear Unit Design

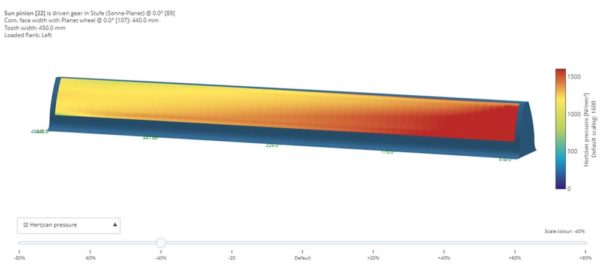

Stober Relies on FVA Workbench for Drive Verification

Read More