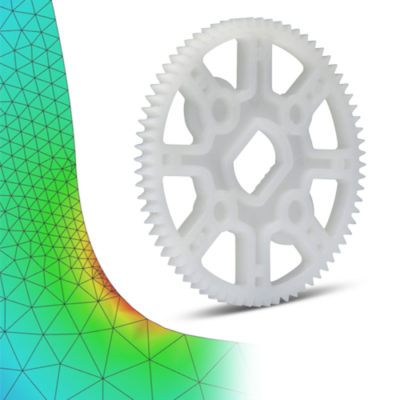

Helical Gears

Having a Ball: The Technology Behind the Ball Drop

The New Year’s Ball Drop wouldn’t be possible without a sophisticated electromechanical system that must operate reliably during the most critical 60 seconds of the year.

Read More

NORD Powers Intralogistics Systems with Modular Drive Solutions

Gear units, motors, and variable frequency drives work in unison to transport items quickly and safely across all intralogistics and warehouse operations

Read More