Conveyor Drives

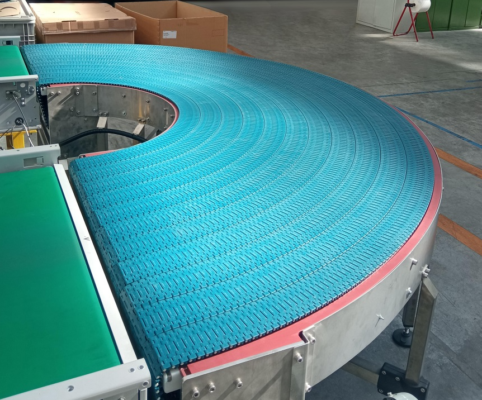

Regal Rexnord Launches the Rexnord Curve System with 1540 Series MatTop Chain

Drop-in system offers tightest inner radius in the market for reduced footprint

Read More

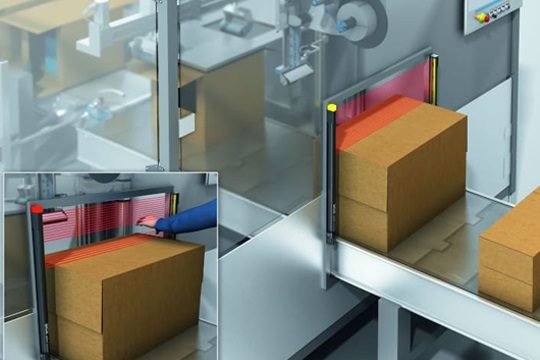

Is This the Restaurant at the End of the Universe?

McDonald's Location Boasts 'Grab and Go' Concept Via Conveyor Drives

Read More

Siemens Sinamics Drive Series Adds Frame Sizes for Higher Power Ratings

Compact drives with an extended power range offer users simple commissioning and operation, plus integrated safety.

Read More