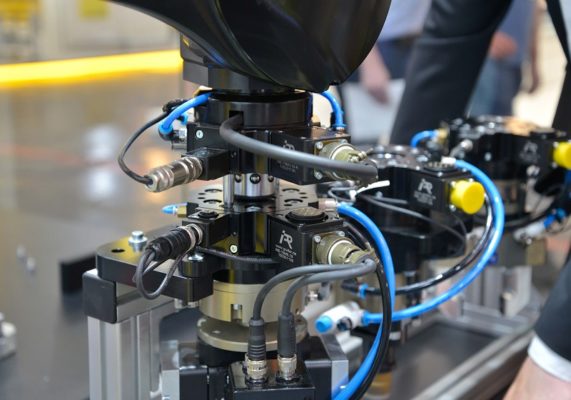

Motion Control

Beyond Bearings: Unleashing the Potential of Ball Splines in Robotic Designs

The often-overlooked benefits of integrating high-speed, multiaxis motion on a single shaft

Read More

2024 Trends in Fluid Power

AI, smart manufacturing, electric vehicles, and product specification highlights industrial shift

Read More