Mechatronics

High Level Automation & System Integration

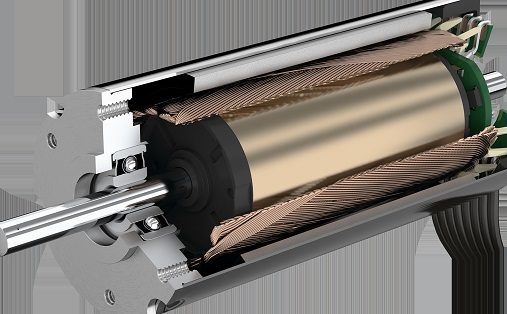

Mechatronics Technologies in E-Mobility Applications

Read More

Mechatronic Methodology

Iljin Electric Collaborates with Siemens Digital Industries on Product Development

Read More