Articles Tagged with ''condition monitoring''

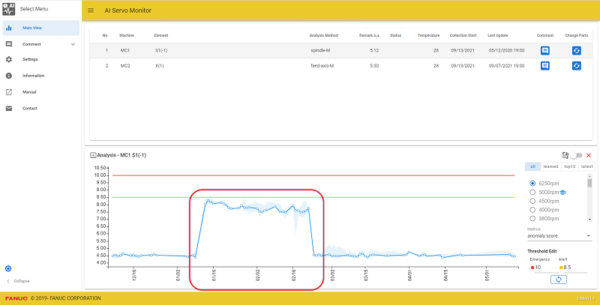

Real-Time Alarms and Historical Data Drive Better Processes

Read More

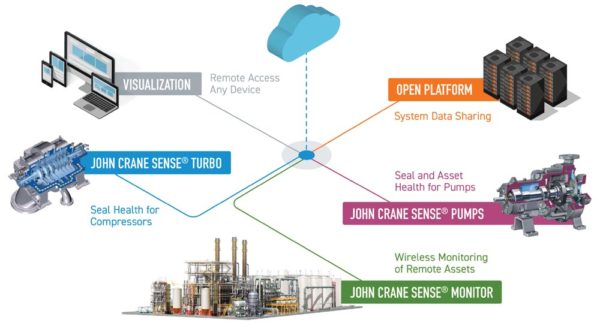

Peering into the Crystal Ball on Condition Monitoring Technology

The future of smart components for motion control systems looks bright

Read More

The Quest for the Perfect Turbine

Condition Monitoring Software Takes Systematic Approach to Wind Farm Maintenance