Articles Tagged with ''robotics''

Schaeffler’s engineering experience provides a clear path toward off-the-shelf as well as customizable design projects for a variety of new and emerging applications.

Read More

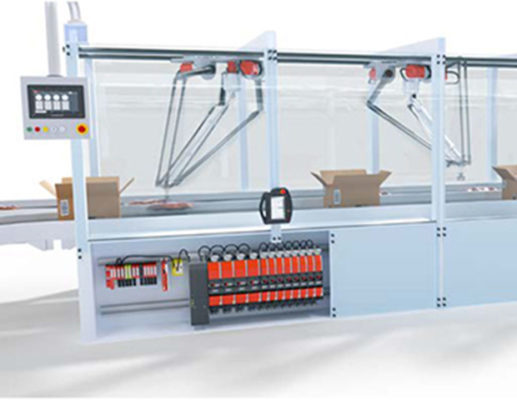

Rapid Advancement at Automate 2022

Robotics and automation will continue to enhance manufacturing production for the foreseeable future

Read More