Articles Tagged with ''PBC Linear''

PBC Linear Provides Solutions for Medical and Lab Automation

Back to Basics: Linear Motion

Read More

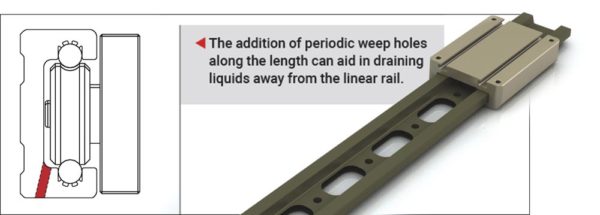

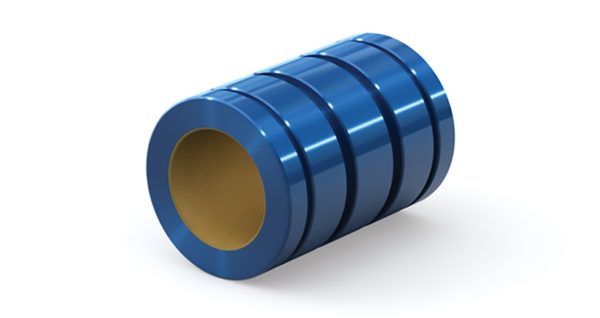

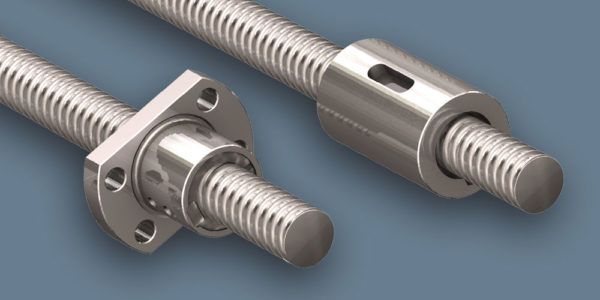

Design Tips for Linear Motion Systems in Washdown Applications

Designing linear motion systems for washdown applications requires careful component selection to solve problems associated with contamination as well as liquid and chemical interactions.

Read More