Avoiding Failure and Downtime

Imperatives to specify gear drives

Gear drives are fundamental in most processing operations, connecting the prime mover to the driven equipment and ensuring that the system has enough torque to effectively move product. Correctly specifying and selecting the proper gear drives for critical applications leads to reliability, greater uptime and profitability.

Selecting the right gear drive ideally brings together the end user, the system designer and the gear drive manufacturer for success.

The user and the system designer must be familiar with the variables that affect performance and service. Similarly, a gear manufacturer must know for what purpose the drive will be used, the demands to be placed upon it and the nature of the equipment it will be driving.

A number of factors enter into the selection of a gear drive, including:

- Service factor

- Drive rating

- Thermal capacity at the site’s ambient conditions

- Speed variation

- Equivalent horsepower

- Drive ratio

- Duty cycle

- External loading on the gear drive’s shafts

- Mounting configuration

- Physical size

All must be carefully evaluated to make the right decision. Consider that tooth surfaces showing signs of wear or pitting should be candidates for future preventive maintenance programs. Additionally, fracture of a gear tooth will not only put the gear drive out of service but could possibly do damage to bearings and shafts.

Specifying a Gear Drive—Imperatives

At a minimum, the application loads and configuration must be defined such that a basic gear drive can be selected. The information required is as follows.

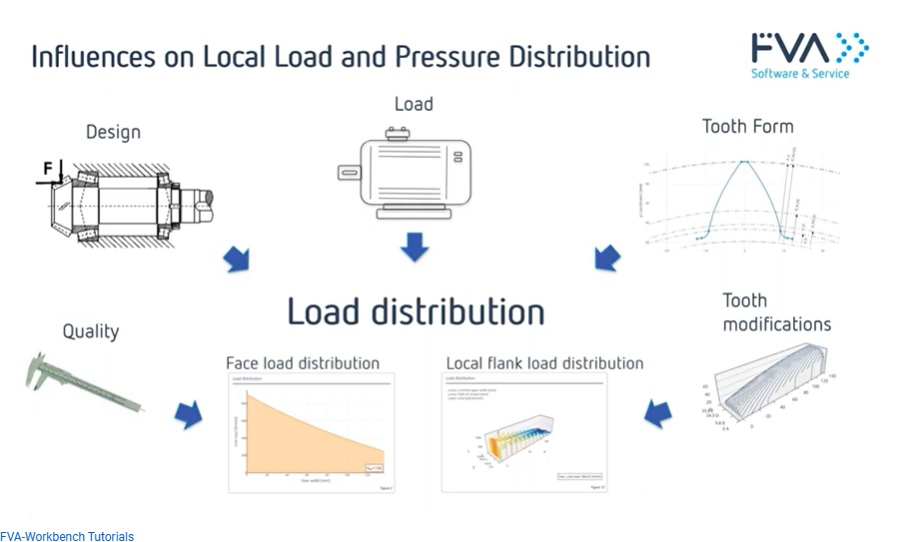

Load and Speed

This is typically the power of the prime mover and its speed. If your motor regularly runs at a lower load than the nameplate, the demand or service horsepower may be used. Gear drives designed and selected in accordance with American Gear Manufacturers Association (AGMA) standards will permit starting and momentary overloads of 200 percent of the unit rating. The unit rating is defined as the maximum power that can be transmitted without exceeding the lowest individual rating of the gearing, housing, shafting, keys, bearings, fasteners and other components of the basic gear drive and auxiliary systems.

Ratio

To arrive at the specific gear ratio required, divide the motor full-load speed by the revolutions per minute (rpm) of the driven equipment. Exact ratios are determined by dividing the actual number of gear teeth by the mating pinion teeth—both of which are whole numbers.

AGMA offers standard ratios. Typical manufacturer’s deviations between AGMA nominal and exact ratios are ±3 percent for a single reduction gear drive, and ±4 percent for a double reduction.

For applications with variable frequency drives, exact gear ratios become less important. In that case, it is best to select a manufacturer’s standard ratio. These will provide lower costs and shorter delivery, with ready availability of off-the-shelf stock spare parts.

Configuration

Gear drives are available in a variety of sizes with various shaft configurations to meet your space requirements. The most popular are parallel shaft, concentric and right angle, with the low-speed shaft either horizontal or vertical. Space should be allowed to access areas such as the lubrication points, the dipstick and the inspection cover.

Service Factor (SF)

Most applications have startup loads, overloads and expectations for life and reliability that cannot be completely captured in the motor loads. The minimum service factor (SF) is a variable that includes the combined effects of stress cycle, reliability and overload factors. It is used to calculate an equivalent horsepower. Application and service duty play an intricate role in determining the proper SF. Appropriate values of SF are determined by field experience. AGMA Standard 6013-B16 (metric 6113-B16) for enclosed speed reducers also contains a listing of applications with their recommended service factors.

A higher SF or larger gear drive size should be selected when peak running loads are substantially greater than normal operating loads. For example, an application that places a torque load on a drive in excess of its rated capacity will inevitably result in distress and, in severe cases, breakage.

Gear drives that are supplied in combination with electric motors may be designated with a service class number such as I, II or III rather than a numerical SF. Class I, II or III are equivalent to SF values of 1.0, 1.41 or 2.0, respectively. Service class and service factor can be used interchangeably. However, numerical designations are preferred because service class does not accommodate intermediate values of SF.

Special consideration for the type of prime mover shall be used as well for determining service factors.

Published service factors are only the minimum recommended for a given application. Some applications require special procedures and may need to be referred to the drive manufacturer. Typical values of SF will not accommodate systems that have serious critical vibrations or repetitive shock loading. The system designer must identify vibratory or shock loading prior to the gear drive selection. These conditions will require changes to be made in the inertia or spring constants of the drive system. Other applications that fall under non-standard selection procedures include a high frequency of starts, reversing service, brake-equipped applications, oversize prime movers, and speed variation or multi-speed applications.

The Falk V-Class gear drive offers cooler operating temperatures, optimal power and advanced technology.

Specifying a Gear Drive—Additional Considerations

Speed Variations

Variable speed applications fall into two load categories: constant torque or constant horsepower. Constant torque occurs when load demand varies proportionally with a change in speed. Gear drives are basically constant torque machines requiring no selection modifications. For a constant horsepower application (load demand is constant regardless of speed), the gear drive must be selected for the slowest speed at which the motor will deliver its rated horsepower capacity. This also applies when a mechanical, electrical or hydraulic speed reduction device is used between a gear drive and a constant-speed AC motor. Variable or multispeed applications also require special considerations to provide adequate splash lubrication at the slowest speed without excessive heating or churning at the higher speed. Forced lubrication is also an option to provide adequate lubrication at the slowest speed.

Ambient Temperature and Altitude

Manufacturers’ catalogs list thermal horsepower ratings based on an assumed set of standard conditions, e.g., a continuous duty cycle at an ambient temperature of 68°F (20°C) and an altitude of up to 2,460 feet above sea level. For other conditions, the thermal horsepower rating must be multiplied by factors provided by the manufacturer for the specific drive under consideration.

Bearing L10 Expectations

The fatigue life represents the theoretical number of cycles before a product experiences a fatigue failure. The fatigue life of the roller bearings within the gear drive are expressed in terms of L10 hours. In order to increase the time between bearing replacements, the L10 life of the bearings can be specified. It is important to consider that high L10 requirements can force the gear drive selection to a larger drive size or expensive lubrication systems.

Service Costs

The service costs of the gear drive may be a selection criterion. The total cost of ownership of the drive is the initial cost, plus cost of any maintenance required throughout the life of the drive. This includes consideration of useful operating life and spare parts if a marginal selection is made. Some drives have a horizontal split housing that makes them easier to disassemble and reassemble for maintenance of the bearings and gearing.

Rexnord PlanetGear gear drives rugged design are proven to meet the operating challenges of the world's most demanding applications.

Accessory Requirements

Your application may have requirements for a backstop, which prevents reverse rotation. It may also have limitations for water or electrical supply that will affect any cooling or lubrication system selections. These should be specified with the other selection criteria.

In addition to all the above, the application may have additional requirements for corrosion protection, condition monitoring, certifications, dimensional fit, paint, testing, etc. It is best to let the gear drive manufacturer know this prior to receiving the final quote so that any increases in costs and lead times can be considered.

The specifications that are provided to the manufacturer will affect the size and cost of the gear drive that is selected. The best cost will come with a gear drive that uses standard parts and options. For example, allowing flexibility for the use of standard shaft diameters can prevent oversizing the gear drive. If a larger-than-standard maximum ratio is required, switching from a 4-pole motor to a 6-pole motor may prevent the need for multiple gear drives. Generally, the cost will increase as the number of requirements increases. Therefore, it’s best to specify the basics and only specify additional requirements if they are absolutely required to successfully run the application.

powertransmission.com/blogs/1-revolutions/post/9824-avoiding-failure-and-downtime