Beyond Bearings: Unleashing the Potential of Ball Splines in Robotic Designs

The often-overlooked benefits of integrating high-speed, multiaxis motion on a single shaft

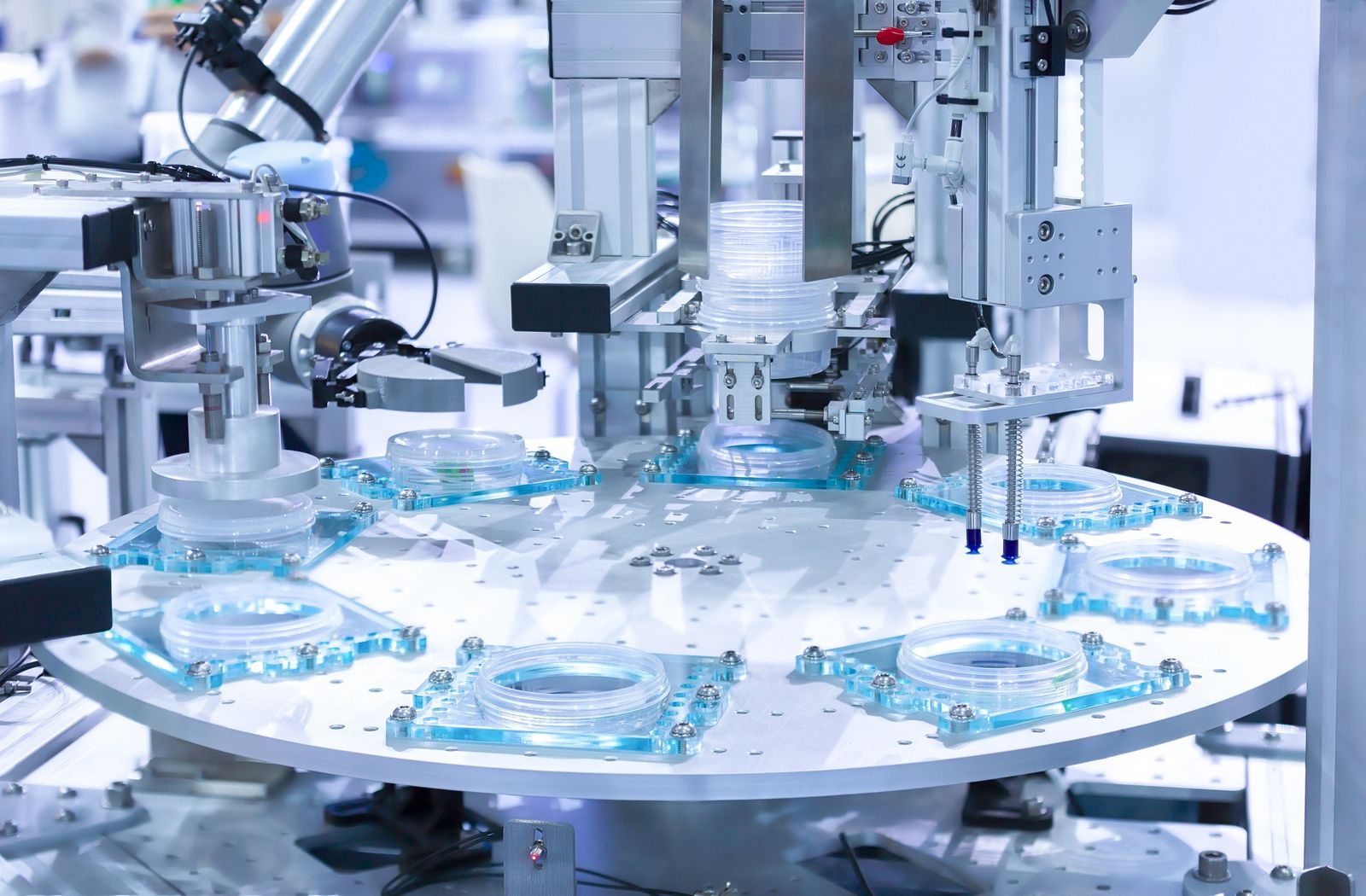

When motion system designers need complex, high-speed, multiaxis motion, they might first think of elaborate, prepackaged robot arms. Or, if they need only a few axes, they might configure a separate profile or round rail for each axis. But hiding between those options is simple and proven ball spline technology. This multiaxis motion solution has existed for years and is still highly relevant to today’s complex motion schemes. Ball splines use a unique architecture integrating rotary and linear motion on a single shaft. This gives them more flexibility to implement complex motion schemes in tighter spaces, providing a two-for-one deal in motion control (Figure 1).

Figure 1—Ball splines, which enable rotary and linear motion on a single shaft, deliver high reliability and life expectancy under varying operating conditions. All figures courtesy of Thomson Industries, Inc.

Integrating Rotary and Linear Motion

Ball splines allow both linear and rotational motion. This is accomplished with a common shaft performing two independent motions (Figure 2). The shaft includes axial ground grooves called “splines” along its length. This also includes a ball spline nut that rides along the axial ground grooves, locking rotational movement or radial moment loads.

Figure 2—Enabling linear and rotary motion on a single shaft, ball splines deliver many benefits to robotic designs, including increased compactness, load capacity, speed, and accuracy.