Nord Exhibits Reliable Solutions at GEAPS Exchange

The 2024 GEAPS Exchange will be open February 24 – 28 in Kansas City, MO and is the best place to see the latest innovative grain industry solutions from Nord Drivesystems. Flexible drive solutions are required throughout the grain sector to power the different systems as well as transport the products from one processing stage to the next. Nord’s highly configurable modular product system provides robust, low-maintenance drive solutions adaptable to a variety of applications including drag conveyors, belt conveyors, rotary valves, screw conveyors, bucket elevators, and more. Their efficient drive systems deliver a long service life and reliable, continuous operation to safeguard end-product quality. Visit NORD at GEAPS Booth #2717 to learn more about these specialized solutions:

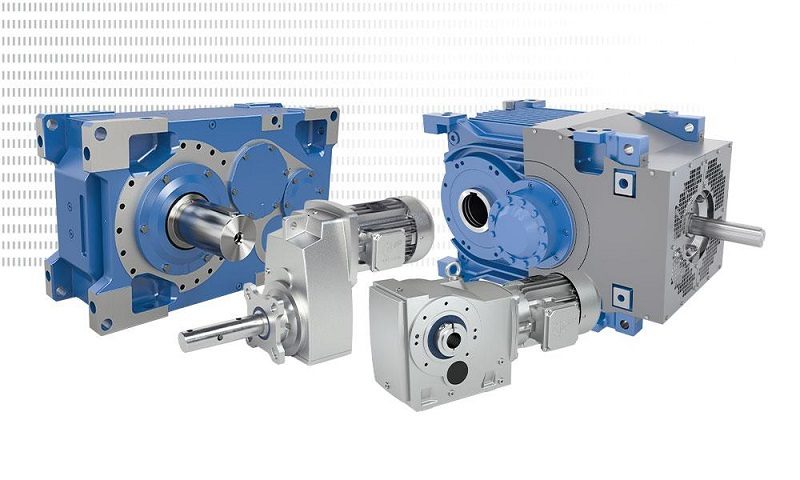

Maxxdrive Industrial Gear Units deliver output torques up to 2,495,900 lb.-in and are an ideal heavy-duty solution for applications such as bucket elevators, agitators, mixers, mills, drums, or crushers. Available in right-angle and parallel designs, these units feature high quality, low friction bearings and a robust one-piece housing to ensure significant load capacity, long service life, and quiet operation. Extensive input options, mounting designs, and cooling options are additionally configurable to meet application requirements.

Maxxdrive XT Industrial Gear Units are a two-stage, right-angle gear unit optimized to achieve maximum thermal capacity with their unique housing geometry. A strongly ribbed design in combination with an axial fan and air guide covers enhances airflow to prevent the unit from overheating at maximum power.

Unicase Helical Bevel Gear Units (high permissible radial forces for drag conveyors) are a robust solution engineered with a cast iron Unicase housing, infinite life gearing, and high permissible radial force ideal for drag conveyors. These units are highly versatile and feature extensive configurable options to adapt to specific application requirements.

The Screw Conveyor Package from Nord is a compact, cost-effective solution for Unicase parallel shaft gear units and Unicase helical bevel gear units in screw conveyor applications. Unlike traditional drives, Nord’s design features a directly coupled gearmotor or NEMA C-face input, eliminating the need for top motor mounts, pulleys, belts, and guards. Not only does this design minimize parts for easier system maintenance, but it also increases reliability, drive performance, and safety.

Nord’s line of synchronous and asynchronous motors is designed to perform efficiently and safely even in harsh conditions or where extremely heavy loads are moved. As many grain applications include finely ground raw materials, the atmosphere throughout plants can often be permeated with dust particles, requiring the drive solutions to be explosion proof.